Reduction of Disinfection Byproducts

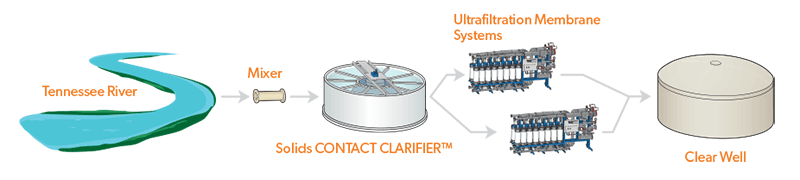

Solids CONTACT CLARIFIER™ and Ultrafiltration Membrane System

Expanding Service

Northeast Alabama Water District (NEAW) services 15,200 connections within 2,052 square miles, resulting in a very large distribution area. Increasing populations expanded the service area and demand even more, creating the need for a larger water treatment facility. To increase capacity and bring water treatment closer to its residents, NEAW and Constantine Engineering constructed the innovative High Point Water Treatment Plant in 2010.

High Point receives its raw water indirectly from the Tennessee River. River water is pumped 5 miles and over 700 feet in elevation to a 4.2 million gallon storage reservoir at the plant location. Managing disinfection byproducts (DBPs) within large distribution areas is difficult at best. Large distribution areas, long chlorine contact times, dead zones, and regrowth contribute to high DBPs. By removing dissolved organic carbon (DOC) in the clarified water, DBPs are minimized.

| DBP | MCL | Prior Levels | Present Levels |

|---|---|---|---|

| TTHM | 80 μg/L | 57 μg/L | 26 μg/L |

| HAA5 | 60 μg/L | 44 μg/L | 26 μg/L |

Equipment Selection

After completing a comprehensive study, the engineer selected enhanced flocculation clarifiers and membrane filtration, specifically solids contact clarifiers and ultrafiltration, as the best method to treat for DOC and turbidity. The plant was also designed to allow for the addition of granular activated carbon (GAC) or powder activated carbon (PAC) in the future, if needed. To remove organics and improve water quality, WesTech was contracted to supply the majority of the process equipment for the High Point Plant.

WesTech’s solids CONTACT CLARIFIER™ is an enhanced flocculation device with internal solids recirculation, gentle flocculation, and gravity sedimentation in a single unit. Compared to a conventional clarifier, high volume internal solids recirculation and low floc shear are provided by the solids CONTACT CLARIFIER, while using less horsepower.

| Quantity | 2 units |

|---|---|

| Design flow | 770 gpm/unit |

| Size | 32 ft2 |

| Hydraulic loading rate | 0.9 gpm/ft2 |

| Basin detention time | 150 min |

| Motor HP | Rake arm drive: 0.5 Impeller drive: 2 |

| Coagulant dose | Range: 11-37 ppm Average: 21 ppm |

Through total organic carbon (TOC) removal, the High Point Water Treatment Plant has seen reduced DBP production due, in part, to the effectiveness of the solids CONTACT CLARIFIER. By effectively reducing TOC and turbidity, solids CONTACT CLARIFIERS have demonstrated their ability to provide excellent pretreatment to membrane filters. The need for chemical cleaning of the filters is decreased with the removal of TOC, in turn increasing the efficiency of the membrane filter.

The WesTech Ultrafiltration Membrane System has a pore size of 0.01μm, providing the highest level of pathogen and particulate matter removal available for low pressure membrane filters. The ultrafiltration membrane system also consistently produces the highest possible quality filtrate, with greater than 4 log removal of cryptosporidium and giardia.

| Quantity | 2 trains 60 total modules |

|---|---|

| Flow | 1,475 gpm |

| Design flux | 45 GFD |

| Recovery | 95% |

| CIP frequency | 30 days |

WesTech’s solids CONTACT CLARIFIER and Ultrafiltration Membrane System work together to improve High Point’s overall water quality by reducing turbidity, removing pathogens, and meeting secondary standards.

Customer Satisfaction

The new High Point facility has been online since January 2011, and has been a great improvement to the Northeast Alabama Water District. As seen in the table below, turbidity and TOC have been reduced to meet or exceed required levels. Water quality has increased and operations and maintenance have been simplified.

The community and NEAW alike are pleased with WesTech’s installation of this new equipment. Operators were especially pleased with the extra level of training provided by WesTech. “WesTech was real easy to work with, and helpful with sending people to train the operators. We’re also getting real good numbers,” said Mike Smith, compliance operator.

| Raw Water | After Solids CONTACT CLARIFIER | After Ultrafiltration | |

|---|---|---|---|

| Turbidity | Range: 11-585 NTU Average: 24 NTU |

1.0 NTU | 0.014 NTU |

| UV 254 | 0.057 cm-1 | 0.022 cm-1 | 0.018 cm-1 |

| TOC | 2.5 mg/L | 1.6 mg/L | 1.6 mg/L |

| Color | 10 Pt-Co | n/a | 0 Pt-Co |

| Iron | 0.14 ppm | Non-detect | Non-detect |

| Manganese | 0.06 ppm | 0.01 ppm | Non-detect |

| Temperature | 6-80°C | n/a | n/a |