RapiSand™ Pilot Reduces Phosphorus to Low Levels

Ballasted Flocculation Technology Application

Problem

Phosphorus reduction is a growing concern for many wastewater treatment plants (WWTPs), and with good reason. Finished phosphorus levels of less than 0.1 mg/L as phosphorus (0.1 mg/L–P) is an increasingly common requirement in many places. WesTech has extensive experience in both full-scale and pilot-scale phosphorus reduction to these low levels.

WesTech recently conducted a pilot study to demonstrate the RapiSand™ ballasted flocculation process’ ability to achieve low-level phosphorus outlet requirements at the Central Davis Sewer District (CDSD) WWTP in Kaysville, Utah.

Analysis of Alternatives

CDSD was selected for the pilot site because of the plant’s history of innovation and commitment to improving its wastewater treatment and solids management. While CDSD is able to meet a current discharge limit of 1 mg/L–P, the potential for more stringent future limits created interest in evaluating alternative technologies.

The plant has a split treatment system, where it treats part of the flow with a trickling filter system and the rest through an oxidation ditch system. WesTech conducted jar testing on effluent samples from both treatment trains and determined the oxidation process to be the best choice for pilot testing.

Recommended Solution

The primary goal of this study was to determine if the RapiSand could reduce the effluent’s total phosphorus to below 0.1 mg/L–P with optimized chemical dosing, and below 0.06 mg/L–P with increased chemical dosing. The RapiSand pilot is a trailer-mounted unit with a full laboratory and remote operation capabilities that are available via a mobile-phone connection. The trailer also includes all necessary chemical feed equipment.

The RapiSand system is designed to remove suspended solids at hydraulic loading rates of 25 gpm/ft2 (60 m/h). These rates are achieved through ballasted flocculation: coagulation and flash mixing followed by the addition of polymer and a weighting agent (microsand) in a dual-stage flocculation step. The polymer and sand bind rapidly to the suspended particles, which allows for higher rise rates and shorter hydraulic detention times (approximately 10 minutes) compared with conventional flocculation and sedimentation. Because of this, the RapiSand can decrease the footprint of a traditional flocculation and sedimentation system by more than 95 percent, depending on the application.

Implementation

The pilot team used laboratory jar testing to identify optimum chemical types and quantities. The team selected alum as the coagulant because the plant already uses it on-site, and a dry anionic polymer because of the polymer’s performance at lower doses. The pilot testing took place in February and March of 2020.

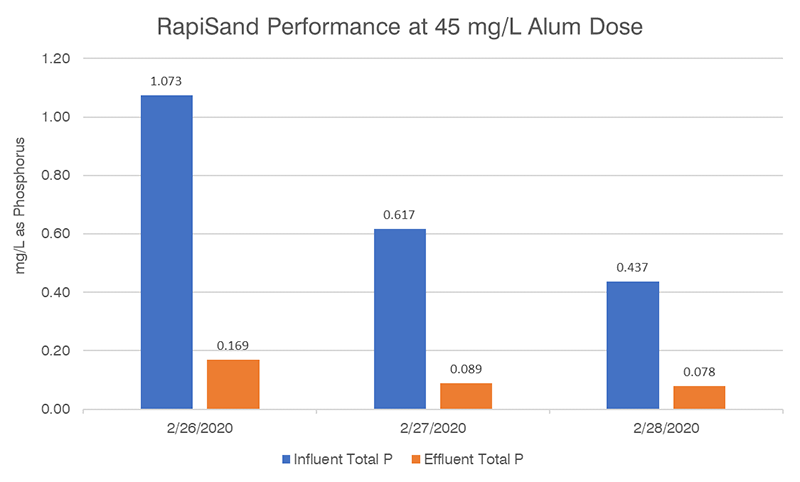

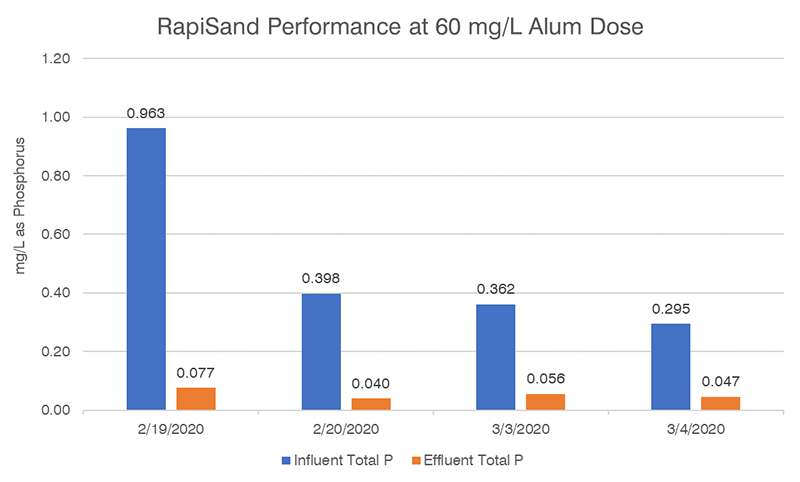

Chemical dosing was varied during phases of the pilot to test the effectiveness of the RapiSand process in removing phosphorus. Alum dosing was dependent both on the influent and target effluent concentrations of phosphorus. Phosphorus feed during the study ranged from 0.26 to 1.07 mg/L–P. Coagulant dosing ranged from 0 to 60 mg/L, with an average of 45 mg/L. Anionic polymer dosing ranged from 0.5 to 1.5 mg/L, with optimized results found at 1.0 mg/L for typical influent compositions.

Results

Coagulant doses around 45 mg/L were typically effective in reducing the outlet total phosphorus to below 0.1 mg/L–P. Higher doses (around 60 mg/L) were effective in decreasing total phosphorus to below 0.06 mg/L–P.

The RapiSand met the goals outlined in the study and demonstrated the ability to effectively reduce phosphorus to low-level applications. The system’s performance was consistent and responded quickly to changes in inlet water quality, as well as daily equipment startups. The water produced through the pilot study would meet or surpass typical treatment requirements for plants operating under low-level phosphorus outlet standards. The RapiSand technology can be readily applied to other plants with phosphorus treatment needs.