Bolivar WTP Turns to AERALATER®

Cost-Effective, Low Maintenance Iron/Manganese Removal

Problem: Iron and Manganese Groundwater Contaminants

The drinking water supply for the Village of Bolivar, New York, comes from two water treatment plants, both of which use groundwater as a source water. The treated water from Bolivar is combined with the treated water from the nearby town of Richburg to provide drinking water for both communities, servicing about 1,650 customers, with the local school being the largest customer.

The Bolivar treatment plant uses water from three wells that contain various levels of iron and manganese, measuring on the average of 0.59 mg/L of iron and 0.75 mg/L of manganese. Because the original treatment process was only using chlorine and anti-corrosion chemicals, a more effective treatment process was needed to meet the treated water quality requirements using a proven treatment system.

When Bolivar received funding from the state revolving loan program, along with federal funding, to build a new water treatment plant, it hired the engineering firm of Clark-Patterson Lee of Olean, New York, to design the new plant. Even with low-interest loans, the city required a system that was cost-effective to install, simple to operate, and low maintenance.

Solution

WesTech Engineering’s agent for the area, Koester Associates, coordinated the project with the engineering firm and the installing contractor. The engineer selected a 12-ft-diameter General Filter AERALATER® Type II system from WesTech to treat the iron and manganese in the raw water. The AERALATER system is a packaged groundwater treatment system that combines aeration, detention, and filtration in a single unit to remove common groundwater contaminants (e.g., iron, manganese, radium, and arsenic) and produce treated water to the regulatory requirements.

The packaged system uses an induced draft aerator to saturate the raw water with oxygen. The raw water is introduced in the top and distributed evenly using a distribution tray. Target nozzles spray the water across the top of the media. This design eliminates the need for high-pressure spray nozzles, reducing the pressure required for the system and the overall operating cost.

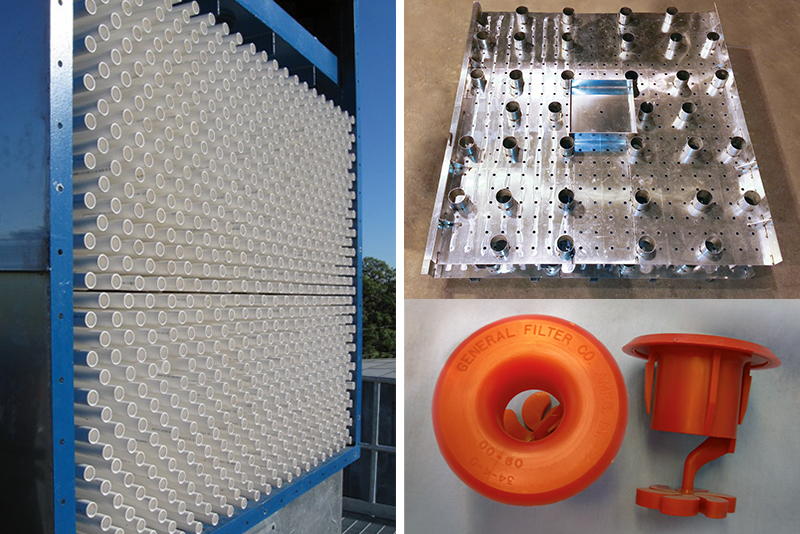

Right: Distributor trays and nozzles ensure the dispersal of water to all areas of the aerator.

The media is made of thin-wall PVC pipes spread on 2-inch centers with 2-inch spacing. The pipes promote air contact with the water, saturating it with oxygen from the atmosphere, which is an extremely effective means of precipitating iron. The tray slats are removable to allow cleaning of iron that precipitates in the aerator. An induced draft blower pulls atmospheric air through a screened opening designed to allow air flow with minimal pressure drop. The distribution tray has air stacks to allow the air to flow freely out of the unit without entraining water and to eliminate the pressure drop associated with tray systems. The bottom of the aerator is open to the detention tank. A chemical oxidant is added and mixed into the influent flow prior to the detention section using the static mixer located under the aerator.

The detention tank section is designed to have a minimum of 30 minutes of detention time prior to the filter media. At typical pH and temperature values, this is adequate time for the oxidation and precipitation of iron and manganese using oxygen and potassium permanganate, respectively. Inside the detention tank are manways for accessing the filters below. The level in the detention tank is controlled by a valve connected to a float assembly. As the water level in the tank rises, the valve closes, increasing the pressure to the well pump and reducing the flow. If the water level in the detention tank drops, the valve opens, allowing more flow to enter the system. In addition, a pressure transmitter mounted in the detention tank monitors the water level and provides a signal to the effluent modulating valve via the programmable logic controller (PLC) to maintain the proper operating water level. Maintaining the water level in the detention tank ensures that there is always adequate head pressure to backwash the filters.

The water from the detention section then flows through a set of face piping and into a four-cell filtration system. The filter uses 24 inches of treated 0.6 mm to 0.8 mm anthracite media. The filter removes the precipitated iron and manganese particulates. Filter backwashing is accomplished by closing the system effluent valve, the closing the inlet valve followed by opening the backwash waste valve for the filter cell to be backwashed. Pressure from the water level on the detention tank forces water through the three remaining filter cells that are in service and into the common underdrain. This treated water flows up through the filter cell being backwashed, where the backwash water is collected in an over-drain and flows out the backwash waste valve to waste. The remaining cells are backwashed in sequence until all have been backwashed. The entire system then is brought back into service.

Because the system is backwashed using the in-service filter cells, this eliminates the need for backwash supply pumps and tanks to bring system water back for backwashing. This makes the overall system more efficient, reducing operating costs for the Village of Bolivar.

The system is constructed of high-quality aluminum, which eliminates corrosion and reduces maintenance at the facility. The unit is manufactured in three primary sections: the aeration section, the detention/filtration section, and the filter face piping. Thus, the installation consists only of attaching the aerator section, attaching the face piping and valves, installing the filter media, and hooking up the power to the aerator blower. This reduces the overall installation cost, saving money for the Village of Bolivar and its ratepayers.

Unique System Features

The AERALATER system for the Village of Bolivar has a number of unique design features. Flow control is done using a modulating effluent valve, which maintains the flow based on the water level in the detention tank and matching the required effluent flow with the flow rate of the well pumps. The AERALATER unit will operate when water demand is called for from the system or to provide adequate flow for the backwash process.

The effluent valve is a K-Flo butterfly valve with a Rotork electric motor actuator to provide an automated flow control process. The remaining valves (filter cell inlet and backwash waste, backwash rate set) on the unit are Bray butterfly valves with manual actuators. Therefore, the primary operation of the AERALATER system is completed manually, which provides for a simple system and allows for the operator to be more closely involved with the unit system operation.

The filter media consist of 24 inches of manganese ANTHRA/SAND™ treated 0.6 to 0.8 mm effective size media. Manganese ANTHRA/SAND filter media provides an effective means for removing iron and manganese from water supplies by conditioning the filter medium to form a special coating to granular media. Conditioning is completed after the media has been installed in the filter. The manganese removal capacity of manganese ANTHRA/SAND media is approximately equal to that of manganese greensand when measured on a surface area basis and offers a cost-effective alternative to manganese greensand. Because the base filter media consists of anthracite, which has a larger media grain size compared to greensand, this can have the advantage of increasing filter run lengths and making it practical for use in filter systems.

The AERALATER tankage (detention and filter sections) is wrapped with Armacell 1-inch thick roll insulation to provide a vapor barrier and prevent issues associated with condensation.

A flexible membrane was used for roof flashing to provide an easy, water-proof sealant method between the AERALATER unit and the roof of the water treatment building. The sealant is a cold-fluid applied reinforced polyurethane flashing system by Kemper Systems. Previous methods primarily used a flashing ring welded on the tank that required confirming the roof location for proper installation. The Kemper Systems method eliminated this issue. Since the plant’s start-up in August 2015, no problems have been reported with the flashing.

System Performance

Since the start-up of the system in August 2015, the Bolivar WTP has reported good treatment performance and no issues with the operation of the AERALATER. The plant currently treats around 90,000 gallons per day, which gets combined with the Richburg plant effluent. The current chemical treatment includes potassium permanganate for oxidation in the AERALATER system and chlorine gas dosed into the clearwell for post treatment disinfection. The filter backwash water is sent to a pit, and then sent to the wastewater treatment plant.

“I love it. I really like this system ... It’s a vast improvement over what used to be here.”

When asked how he felt about the AERALATER, Wayne Stonemetz, operator of the water treatment plant, commented: “I love it, I really like this system, and it’s great, simple and has no problems with it. It’s a vast improvement over what used to be here.” (The previous treatment was only chlorination and anti-corrosion chemicals). Due to the simplistic configuration of the packaged treatment system and its operational demands, the unit operates in a manual mode.

The treated water quality is measuring the iron and manganese levels at <0.05 mg/L and <0.077 mg/L, respectively. The system has met or exceeded the town’s requirement for high-quality water, while offering simple operation and maintaining the overall economy expected of a packaged groundwater treatment system.