Clarifying Castaic Lake With SuperSettler™

Increasing Capacity

The Castaic Lake Water Agency (CLWA) treats water from Castaic Lake using two water treatment facilities. These facilities provide clean water for 25 percent of the Santa Clarita Valley. One of the facilities, the Earl Schmidt Filtration Plant (ESFP), was built in 1980 with a capacity to treat 28 MGD. After years of population growth, the plant struggled to meet increasing demands. In 2003, the CLWA began making plans for plant expansion.

Equipment Selection

CLWA’s plans for expansion included installing new flocculation chambers and sedimentation basins. Due to space limitations, engineers required equipment that would efficiently clarify, but could be contained in a small footprint. The agency decided that plate settlers were the best solution to meet its sedimentation needs.

WesTech was selected to provide two SuperSettler™ inclined plate clarifiers combined with two flocculation chambers to enhance sedimentation. For this project, WesTech worked with Meurer Research Inc. to provide the inclined plate packs.

| Quantity | 2 trains |

|---|---|

| Design flow | 750 gpm |

| Max hydraulic loading rate | 0.40 gpm/ft2 |

| Effective plate surface area | 1,875 ft2 |

| Spacing between plates | 2.4 in |

| Inclined plate angle | 55° |

| Size (per train) | 28 ft x 11 ft x 26 ft high |

SuperSettler plate clarifiers are designed for uninterrupted settling in a footprint one-tenth the size of a traditional settling basin. WesTech provides plates made of stainless steel, PVC, and FRP.

At the ESFP, anionic polymer is added to raw water in a rapid mixing chamber. The chemically treated water then enters the flocculation tanks, which promote particle interaction. WesTech configured its flocculation chambers for ideal floc formation.

| Coagulant dose | 0.47 mg/L |

|---|---|

| Backwash recycle | 0.37 mg/L |

| Filter run time | 59-85 hrs |

Water then enters the SuperSettler through the side of the tank, minimizing the disturbance of the settled material and preventing contamination of the clarified effluent. The openings at the top of the plate assembly are designed to create a pressure drop across the collection channel, ensuring that flow is uniformly distributed between the plates. This patented flow control feature enhances separation performance by utilizing the full area of the plates. Settled material collects in a bottom hopper, where it is discharged.

Clarified effluent is then pumped for further filtration and disinfection. A portion of filter backwash water is recycled to aid in flocculation and sedimentation.

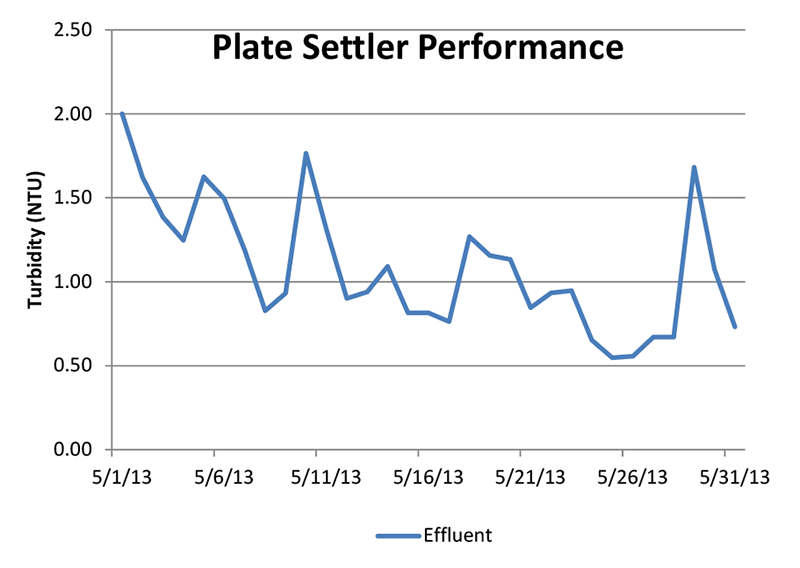

WesTech specifically designed and configured the flocculation basins and plate settlers to consistently produce water with effluent turbidity under 2 NTU.

Customer Satisfaction

Plant operators are pleased with the performance of the plate settlers. With the help of WesTech’s SuperSettler inclined plate clarifiers, CLWA was able to increase total plant capacity, in a small footprint, to 56 MGD while consistently meeting turbidity requirements.