Pretreatment Equipment Helps Produce High Quality Water

Expanding Service

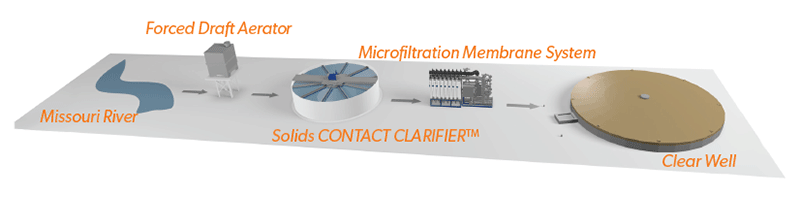

Water District No. 1 (WaterOne) serves more than 400,000 residents in the growing community of Johnson County, Kansas. Johnson County is one of the nation’s fastest growing areas, and in order to meet current and future demands for purified drinking water, WaterOne required expansion.

The existing location of the treatment facility did not have the space to house new equipment. Therefore, to accommodate for new equipment, WaterOne chose a new site at a neighboring location. WaterOne contracted with Black & Veatch to design the new Wolcott Water Treatment Plant.

| EPA Standards | Goal | Effluent | |

|---|---|---|---|

| Total alkalinity (as CaCO3) | 300 ppm | <80 ppm | Average: 62 ppm Range: 45-77 ppm |

| pH | 8.5 | >9.0 | Average: 9.5 Range: 9.2-9.8 |

| Total hardness (as CaCO3) | 400 ppm | 200 ppm | Average: 123 ppm Range: 73-152 ppm |

Equipment Selection

The new Wolcott Plant treats water drawn from the Missouri River, so engineers required equipment that would treat for hardness, turbidity, iron, and manganese. Engineers desired equipment that would produce high-quality water with low chemical dosage at a low cost. WesTech was chosen to help meet these objectives by providing two forced draft aerators and two solids CONTACT CLARIFIERS™.

| Quantity | 2 |

|---|---|

| Sizes |

167 ft dia |

| Design flow rate | 30 MGD each |

| Total detention time | 283 min 172 min |

| Motor HP | 40 HP each |

| Quantity | 2 |

|---|---|

| Footprint | 144 ft2 |

| Design flow | 5,250 gpm |

| Loading rate | 24.11 gpm/ft2 |

| Media | 6-in PVC slats |

| Blower rate | 20,900 cfm |

| Air/water ratio | 4.0 cfm/gpm |

The first step of treatment at WaterOne’s Wolcott Water Treatment Plant is WesTech’s Forced Draft Aerators. After chemical dosing, raw water is pumped into the forced draft aerators where iron and manganese are oxidized, creating floc and reducing CO. With few moving parts and minimal maintenance, forced draft aerators efficiently remove iron and manganese at a much lower operating cost than other systems. Following the aerators, water is pumped to the clarifiers for softening and sedimentation.

WesTech Solids CONTACT CLARIFIERS are enhanced flocculation devices with internal solids recirculation, gentle flocculation, and gravity sedimentation in a single unit, making them an ideal choice for softening and clarification.

Compared to the conventional clarifier, the solids CONTACT CLARIFIER provides high volume recirculation and low floc shear, while using less horsepower. In the same clarifier basin, softening and clarification occur simultaneously, improving efficiency and reducing overall footprint.

Because alkalinity is maintained in the clarifiers, WaterOne is able to settle a large amount of suspended solids, better preparing water for filtration. Following the clarifiers, membranes using microfiltration technology further treat water before it is sent on for distribution.

WesTech Solids CONTACT CLARIFIERS greatly improve the lifespan and cleaning frequency of membrane filtration. Enhanced clarification also reduces chemicals needed to maintain the membrane filtration system.

Exceeding Expectations

Operators are very pleased with the performance of WesTech’s Forced Draft Aerators and Solids CONTACT CLARIFIERS. They acknowledge that, with the help of WesTech’s equipment, they consistently achieve set goals for total water hardness, pH, and alkalinity.

Because of the environmentally friendly and technologically advanced equipment at the Wolcott Plant, WaterOne received the 2011 Engineering Excellence Award, in the water resources category, from the American Council of Engineering Companies (ACEC) of Kansas.