Thickening Bauxite Tailings

HiDensity™ Paste Thickeners

Improving the Process

A bench and pilot-scale study program was conducted to evaluate paste thickening of bauxite tailings for a solids throughput rate of 360 t/h and a flow rate of 5,300 m3/h. The tailings particle size distribution was characterized as D40 minus 60 microns. The client’s objective was to maximize water recovery at the plant and dispose of the tailings by stacking without a pond.

The results of the testing defined the expected underflow densities, diameter, and design of a WesTech HiDensity™ paste thickener. The 45-m-diameter paste thickener was sized to produce a paste with a concentration up to 35 wt% solids, the rheological limit for pumping.

A pilot-scale study was conducted to evaluate the deposition dynamics such as the angle of repose, layer depth on drying period, and drying characteristics during wet and dry seasons in the Amazon region. The standard surface stack methodology deposits the non-Newtonian thickened tailings in layers with a drying period before the discharge is returned to the location for the next layer. Therefore, a continuous discharge is diverted between several locations around the deposition site at a schedule that allows the desired drying between layers.

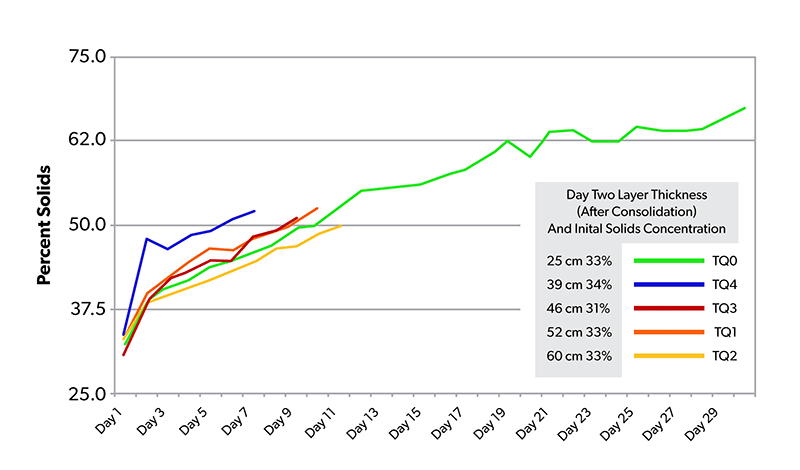

The pilot study used the WesTech 1-m-diameter pilot unit to produce the target underflow paste/thickened tailings that was placed in deposition troughs constructed by the customer. The protocol included layer depths of 25–60 cm, drying during the wet season and dry season, and the angle of repose for the target yield stress ~40 Pa (33–35 wt% solids). The test results showed insignificant variation due to depth and wet/dry seasons. The graph produced by the mine owner shows data from the pilot study. Test TQ0 was during the last part of the wet season. The other tests' drying rates cluster around the wet season drying rate. The uniform drying is due to the angle of repose that the surface stack has, which allows the rain water to leave the surface, as to not restrict the drying of the stack. Cracking begins days following the deposition.

PasteThick Associates designed the paste thickener to produce underflow based on the identified limits of pumping and the required deposition slopes. This project is an example of the systems approach where the paste thickener is designed with consideration of downstream requirements, samples, and rheology measurements that are shared between thickener, pump/pipeline, and geotechnical designer.