Pretreatment at Patterson Pass

Solids CONTACT CLARIFIER™

Background

Zone 7 Water Agency serves nearly 200,000 people in the Livermore-Amador Valley area of Alameda County. The South Bay Aqueduct delivers water from the Sacramento-San Joaquin Delta to the Altamont, Del Valle, and Patterson Pass water treatment plants, after which it is distributed to retail water agencies.

At Patterson Pass, water is detained in a reservoir at the head of the plant. Occasional algal blooms in the reservoir are treated with copper sulfate.

Plant Expansion

The Patterson Pass facility had long been using a modified flocculating clarifier and a cluster of sand filters. This plant produced roughly 12 MGD of treated water. Growing water demands in the Livermore-Amador Valley necessitated a capacity increase. In 2001, Zone 7, along with CDM Engineers and Constructors, broke ground for a plant expansion that would increase to the total plant capacity to more than 21 MGD.

Pretreatment

Based on extensive pilot plant studies, Zone 7 opted to use membrane ultrafiltration in the plant expansion. For pretreatment, WesTech was selected to provide a 102-foot diameter solids CONTACT CLARIFIER™. The plant expansion was completely independent of the treatment line already in operation, and the new solids CONTACT CLARIFIER and the original flocculating clarifier operate in parallel with each other.

Operators have found that when compared to the older model flocculating clarifier, they can use a significantly lower dose of Ferric Chloride. Typical polymer doses are 0.08 ppm for anionic polymer and 1.8 ppm for cationic polymer in the modified flocculating clarifier. To prevent membrane fouling, none are used in the solids CONTACT CLARIFIER. At startup, some operators expressed concern about the abilities of the solids CONTACT CLARIFIER to perform under these conditions, based on what they had experienced with their current equipment. A statistical analysis of settled water turbidity shows that the new solids CONTACT CLARIFIER provides significantly better settled water quality.

Intelligent Solution

The WesTech Solids CONTACT CLARIFIER combines mixing, internal solids recirculation, gentle flocculation and gravity sedimentation in a single unit. The low shear impeller provides high volume recirculation and low floc shear, while expending less horsepower when compared to a conventional unit. Superior clarification provided by the solids CONTACT CLARIFIER extends the life of the ultrafiltration membranes and reduces the amount of cleaning cycles, giving Zone 7 the most value from its membrane ultrafiltration system.

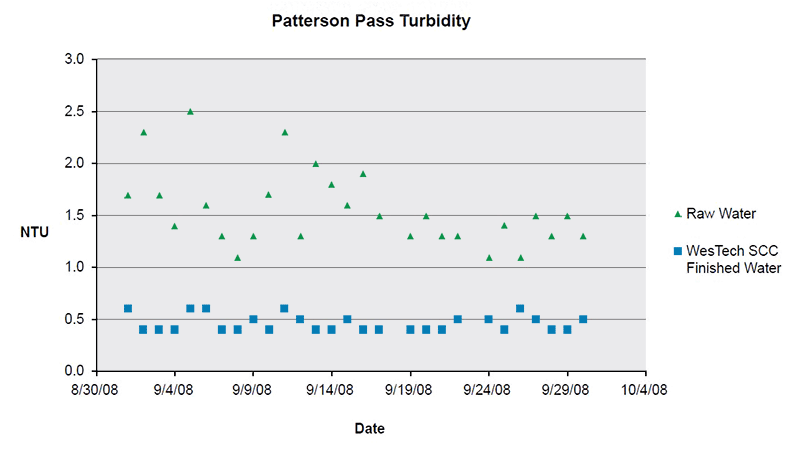

CDM Engineers & Constructors conducted a four week full scale plant performance test in September of 2003. CDM advised that settled water turbidity had been ranging from about 0.6 to 1.3 NTU and iron levels were less than 1.2 mg/L (average ~0.4 mg/L) during the performance test.

These parameters were declared well within performance expectations. Zone 7 provided data for September of 2008, which shows that in that month, influent water turbidity averaged 1.56 NTU, and settled water averaged 0.46 NTU.

Zone 7 has been so impressed with the performance of its WesTech SCC that it is investigating the feasibility of replacing its other clarifier at Patterson Pass with another solids CONTACT CLARIFIER from WesTech.