Single-Stage Acid Mine Drainage

WesTech Turnkey System

Master Plan

Many active and inactive coal mines are found in West Virginia and Pennsylvania. When mining operations cease, coal mines often flood and the overflow can cause adverse effects to surface rivers and streams. Waters from abandoned mines typically have a low pH and the acidic nature brings about elevated iron, aluminum, and sulfate concentrations.

Acid mine drainage (AMD) treatment typically means pumping water from mines and treating the problematic issues before releasing it to nearby surface streams. The final pH of treated waters is 6-9. Iron concentration is reduced by chemical precipitation, typically reducing other metal concentrations as well.

The Shannopin Mine, located in Garards Fort, Pennsylvania, was closed in 1993 and gradually filled with water, threatening to spill over into Dunkard Creek, which empties into the Monongahela River.

Longview Power is located in West Virginia along the Monongahela. The total water requirements for the coal-burning power facility are approximately 7,000 gpm (1,590 m3/h ) for its steam turbines and cooling tower.

As the Longview Power plant was being planned, various Pennsylvania agencies and Dana Mining Company (an affiliate of Longview Power) worked together to develop a plan for treating the water in the Shannopin workings. The resulting drawdown of water would expose the Sewickly coal seam, expanding Dana’s coal reserves, part of which they would mine for use at Longview.

GenPower also proposed to use the effluent water from the AMD facility for process requirements at Longview.

Equipment Selection

Approximately 3,500 gpm (795 m3/h ) of acid mine drainage needed treatment from Shannopin. Samples gathered from Shannopin mine indicated influent levels of 31,300 ppm for total dissolved solids (TDS), 4,180 ppm for iron (Fe), and 21,350 ppm for sulfate (SO4). This water had to be neutralized and treated before discharge to any Pennsylvania stream or use in other facilities. The plan was to convey water to the power plant in a four-mile-long pipeline paralleling a conveyer belt from mines on the border of Pennsylvania and West Virginia operated by MEPCO and Dana Mining Company.

WesTech Engineering, the prime process equipment supplier and contractor for the acid mine drainage treatment facility, proposed to provide and install a single-stage acid rinse water treatment system, which included acid neutralization, solids sedimentation, and a high-density sludge system. All process tankage was to be designed for above-ground installation.

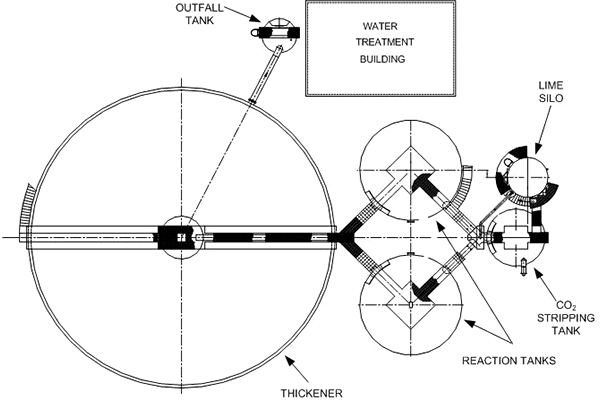

The acid mine drainage treatment plant uses a physical/chemical process where AMD acidity is neutralized by the addition of lime slurry, followed by solids precipitation, which is then sent for separation in a gravity thickener. Specifically, after lime addition, the flow is directed via separate flumes to two reaction tanks. Each reaction tank is 35-ft (10.7 m) in diameter by 17-ft 3-in (5.26 m) in depth and equipped with a surface aerator to provide 250 pounds per hour (113.4 kg/h) of oxygen transfer for iron oxidation. Discharge from these tanks — around 4,200 gpm (954 m3/h ) — enters a flume where the feed is flocculated with a polymer solution. The water then flows to a thickener that is 105 ft (32 m) in diameter with a straight side depth of 15 ft (4.6 m).

Results

Water quality sufficient for permitted discharge to Dunkard Creek is consistently achieved. Effluent water with TDS values less than 8,000 ppm and iron concentrations less than 100 ppm have been observed. Due to the success of the AMD treatment plant, a duplicate plant was built to process water from the Humphrey mine located in West Virginia. Longview Power station was completed and mining of the Sewickly coal seam is ongoing.