CONTRAFAST® Protects Downstream Membrane Filtration System

Dickinson Achieves Softening Without Polymer Addition

Problem

Southwest Pipeline Project, a regional water system owned by the state of North Dakota and operated by Southwest Water Authority, needed additional capacity to meet growing demand in its main service area. To meet this need, Bartlett & West/AECOM designed the new Southwest Water Treatment Plant (SWTP) to treat 6 million gallons per day (MGD) – or 946 m3/h – expandable to 18 MGD (2839 m3/h). Treatment consisted of ozone pretreatment, followed by a high-rate softening clarifier and ultrafiltration (UF).

Analysis of Alternatives

The engineering team considered high-rate options for the clarification and softening process, followed by membranes for the filtration step. This approach presented certain challenges. High-rate clarification and softening processes typically include chemical addition in the form of coagulant and pH adjustment to promote particle destabilization and precipitation, as well as polymeric flocculant aids to promote rapid settling and sludge densification. With high-rate clarification and softening as the first step in a treatment approach, it was important to consider compatibility with downstream processes such as the membrane filtration system. Polymer addition can lead to irreversible membrane fouling if the polymer’s molecular structure, charge properties, and concentration are not taken into account. An additional consideration for polymer restriction is that it can lower operational costs for the plant.

As an expert in pretreatment for membrane filtration, WesTech was able to perform bench-scale testing to evaluate the optimal treatment strategy for SWTP. WesTech’s lab technicians conducted a series of jar tests, achieving turbidity below 10 NTU with less than 10 mg/L of sodium aluminate and no polymer. This testing demonstrated that it was possible to achieve appropriately pretreated water without polymer in a lime-softening application by recirculating solids through the equipment.

In addition to chemical compatibility considerations, the plant would also face operational challenges with a high-rate clarification and softening system. SWTP does not run continuously, but instead operates 8-24 hours a day to match seasonal demands. Solids in the basin would tend to settle and densify overnight. This might cause variance in solids recirculation and densification, complicating system operation.

Recommended Solutions

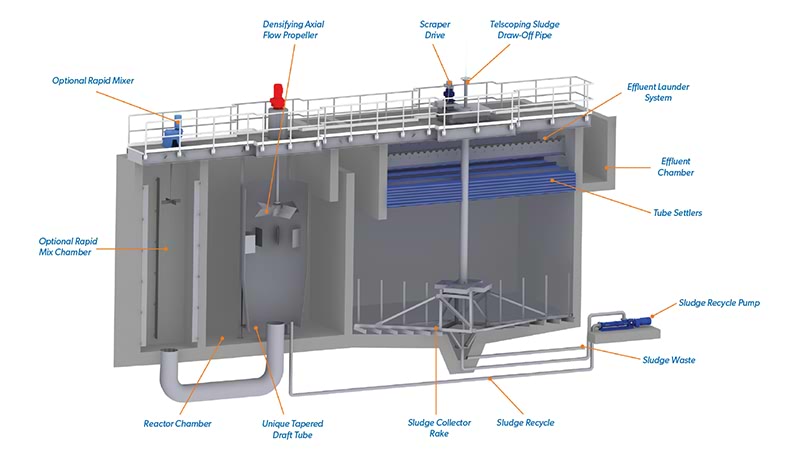

Based on WesTech’s analysis and bench-scale testing, the engineer selected the WesTech CONTRAFAST® as the preferred high-rate clarification and softening technology. The CONTRAFAST is designed for a peak flow rate of 6.5 MGD (1026 m3/h), which meets SWTP’s capacity requirements. Its high-rate clarifier and softener technology reduces the system’s footprint through several process advantages and can provide a dense underflow equal to or greater than a typical gravity thickener in a similar application (greater than 10 percent by weight for lime softening). Compared with a typical flocculation, clarification, and thickening process, CONTRAFAST takes up only 10 percent of the combined equipment footprint.

Implementation

SWTP treats raw water collected from Lake Sakakawea with chloramines in the 90 mile (145 km) raw-water pipeline for primary disinfection. It uses ozone at the facility as a secondary disinfectant. WesTech’s CONTRAFAST equipment softens and clarifies the water prior to membrane filtration.

In the CONTRAFAST process, raw water enters a rapid mix zone where coagulant is added. Next, flow transfers to a reaction zone, where it is combined with recirculated sludge and lime. From there, a high-velocity up-flow transfer zone sends flow from the reaction zone to the clarification chamber, allowing solids to settle and thicken. Tube settlers provide additional settling area to help reduce footprint and improve effluent quality. Dense sludge settles to the basin floor, where it is collected and discharged. Effluent launders collect the clarified water, which then goes to membrane filtration. A portion of the thickened solids are recirculated back to the reactor, and periodic blowdown removes solids from the process as needed.

As previously mentioned, the SWTP has some unique operational challenges resulting from intermittent operation. To ensure consistent performance, WesTech worked closely with the plant operators to define daily startup and shutdown procedures. Specific steps include a steady influent ramp up, recirculation adjustments during startup, and solids inventory management at the end of the day.

Results

WesTech process experts were able to navigate the unique design and operation considerations of the project to provide a high-rate lime-softening clarifier as pretreatment to membrane filtration. The WesTech CONTRAFAST is both highly space and cost efficient, and through testing validation, the use of polymer was successfully eliminated. Three years after the system was commissioned, the average effluent turbidity from the CONTRAFAST was 0.9 NTU, well below performance requirements.

| Lime Dose | Sodium Aluminate Dose | Target Effluent Turbidity | Effluent Turbidity, May 2020 |

|---|---|---|---|

| 36.7 mg/L | 8.09 mg/L | >2 NTU | 0.9 NTU |