New Package Treatment Plant Handles High Turbidity Conditions to Meet Rabun’s Treatment Objectives

Located in Georgia’s northeastern-most county, the Rabun County Water and Sewer Authority (RCWSA) supplies water to approximately 16,000 Rabun County residents within 377 square miles. It also provides wholesale water services to the cities of Clayton and Dillard.

Problem

RCWSA owned and operated an aging conventional water treatment plant (WTP) that used a multi-stage clarification process comprised of flash mixing, flocculation, sedimentation, and filtration. The plant’s influent was water from the Little Tennessee River, a 135-mile tributary of the Tennessee River that flows through the Blue Ridge Mountains. While the Little Tennessee’s water is high quality, it also has a highly variable, or “flashy” turbidity that ranges from 4 to over 600 NTU. Nearing the end of its useful life and in need of repair, the plant was struggling to treat these highly fluctuating solids loadings.

In addition, the existing treatment plant was designed and permitted solely for industrial use and wells that provided potable water for area residents and businesses had begun to fail.

RCWSA’s short-term solution to these problems was to pump water over 15 miles from the Lake Rabun WTP, which was at the southern edge of RCWSA’s service area. This solution was expensive and increased the risk of water loss and potential problems while the water was en route.

RCWSA needed a long-term solution that could provide drinking water for residential as well as industrial use.

Analysis of Alternatives

After considering its options for addressing these problems – namely, to either continue pumping water from the Lake Rabun WTP or to build a new WTP – RCWSA decided to build a new plant in the business park that was currently home to the aging plant. It based this decision on several factors, including the ability to:

- Meet projected demands for municipal water

- Enable lower operational and maintenance costs, and reduce water loss by eliminating pumping from Lake Rabun WTP

- Provide water for residents and businesses that were relying on failing wells

- Provide a backup resource so repairs and improvements to the existing WTP needn’t cause loss of service

- Encourage economic development in the area

Recommended Solution

RCWSA contracted with Precision Planning to evaluate several treatment technologies. Based on a number of factors, including the ability to produce excellent filter effluent quality and deliver good net water production, Precision Planning’s consulting engineer selected the Trident® HS package water treatment plant from WesTech Engineering to meet RCWSA’s residential, business, and industrial needs. (Precision Planning had seen other Trident HS package plants in the state, including a plant in Cummings, Georgia.)

Trident HS package water treatment plants use multi-barrier protection with three stages – coagulation and tube settling, Adsorption Clarifier®, and mixed-media filtration – within a single tank. These all-in-one treatment plants operate at higher hydraulic loading rates than do conventional systems, which makes Trident HS an ideal choice for treating water from flashy, high turbidity water sources such as the Little Tennessee River. Trident HS package treatment plants are also chemically efficient. For example, the Aquaritrol® process controller uses inlet and outlet turbidity signals to automatically adjust chemical dosage, which enables the plant to more efficiently use chemicals than it would with a simple flow-pacing process. (The Aquaritrol is part of the Trident HS control panel.) The new plant requires about half as much chemistry as the older plant, further reducing the cost of delivering reliably clean water to RCWSA’s customers. And the Trident HS’s tube settler removes the bulk of the turbidity, which results in a longer duration between Adsorption Clarifier flushes and filter backwashes, reducing waste.

Because the Trident HS uses high loading rates and reduces the space between treatment flow stages, it has a relatively small footprint. It is also capable of providing effluent that is suitable for both residential drinking water and industrial use.

After choosing Trident HS as the preferred solution, the engineer and WesTech worked together to obtain the Georgia Environmental Protection Division’s (EPD’s) approval for the proposed Little Tennessee WTP. WesTech was able to provide information about several Trident HS plants that used source waters with turbidity rates that were similar to the Little Tennessee River’s, and about one such plant that successfully treats waters with turbidities up to 1,000 NTU.

Implementation

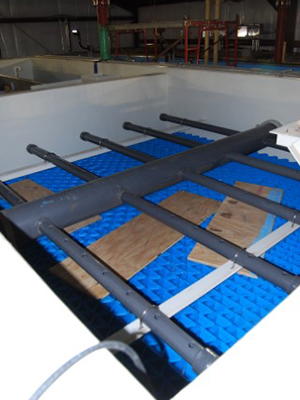

The installation includes two tanks, each of which measures 105 square feet and has a 525 gallon per minute (GPM) capacity.

The process begins with the addition of a cation coagulant and polyaluminum chloride, which are injected into the raw water ahead of the system’s static mixer. An anionic flocculant aid polymer is added just ahead of the tank to assist in floc formation. The chemically treated water enters at the bottom of the unit and flows upward through the section and through the tube settlers, removing most of the solids. The solids settle to the bottom of the section, where the Sludge Sucker™ system removes them from the tank and sends them to waste. Sludge within this section is recycled to the static mixer via a recycle pump. This provides solids contacting, which enhances performance.

The clarified water from the Tube Settler section is collected by a header and lateral system and is pumped to the bottom of the Adsorption Clarifier section. The flow is controlled by a level control system using the control panel programmable logic controller (PLC), an ultrasonic level sensor, and a variable frequency drive (VFD) on the

The Adsorption Clarifier uses buoyant media for further clarification. As solids accumulate and headloss increases, the Adsorption Clarifier is flushed. The WTP flushes its Adsorption Clarifier every six hours using water from the tube clarifier at a flush rate of 10 GPM per square foot of water. The air rate for this process is 5 standard cubic feet per minute (SCFM) per square foot.

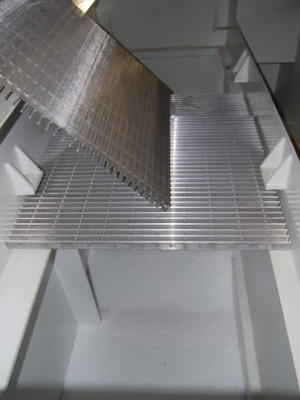

In the final stage, the influent passes through a mixed media filter containing 18 inches of anthracite, 9 inches of silica sand, and 3 inches of garnet to provide a high-quality effluent.

The filter is backwashed with WesTech’s MULTIWASH® filtration process, which simultaneously combines air and water for the duration of the backwash process. This combination vigorously scours media, while specially designed wash trough baffles eliminate media loss. MULTIWASH’s superior media cleaning process prevents chemical and biological fouling, eliminating expensive media replacement or chemical cleaning.

The Trident HS uses the MULTIBLOCK® filter underdrain with Laser Shield™. This direct-retention filter underdrain is constructed of high-density polyethylene (HDPE) plastic, which has a high strength to density ratio and is corrosion resistant. The underdrain’s design eliminates the need for support gravel, provides uniform distribution, and supports an unlimited backwash duration.

The source water for the backwash step is the clearwell, which collects the treated water before the plant pumps it into a 2.5 million gallon storage tank. Two high-service pumps distribute the water to residents and industrial customers, and two backwash pumps provide the water for the MULTIWASH backwash process.

Results

The Little Tennessee WTP has been delivering a total of 1.5 million gallons per day (MGD) of residential and industrial water to the northern RCWSA service area since January 2017. The plant currently services 7,500 local customers and assorted businesses, and with the Trident HS’s 2.8 MGD capacity, will be able to expand its services as the area grows. As an added benefit, the RCWSA can now use the older plant (which has since been refurbished) as a backup when the new plant undergoes maintenance.

Based on performance measurements taken in March 2018, when the influent was 380 NTU, the Trident HS can deliver an effluent with 0.038 NTU and <5 color units, with pH levels ranging from 7.1 to 8.1. This illustrates the Trident HS’s ability to consistently meet safe drinking water regulations and special water quality needs for the Little Tennessee WTP’s customers, now and for years to come.