Trident® Package Plant in Oregon Reduces Turbidity

Water Treatment Plant Expansion

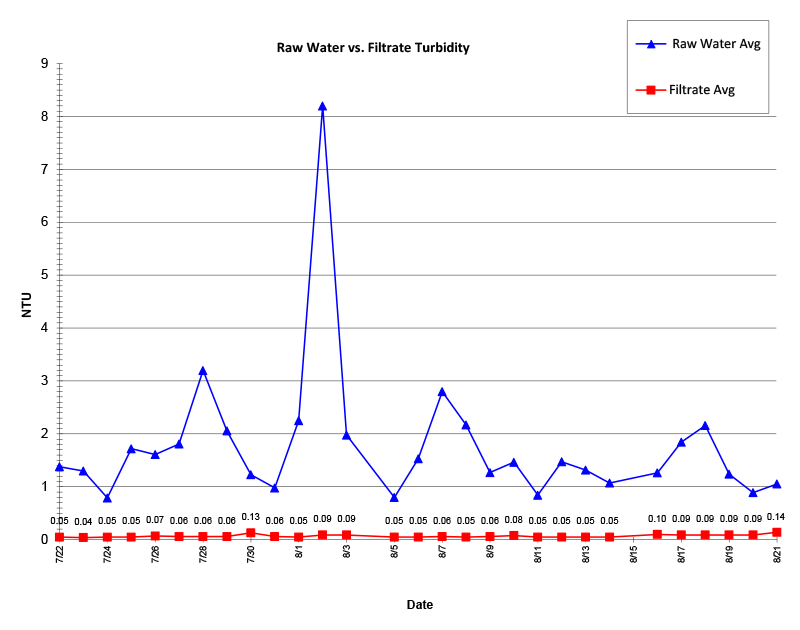

The water treatment plant in Ontario, Oregon, treats high-turbidity water from the nearby Snake River. It serves more than 3,500 homes, industries and businesses, both inside and outside the city limits. With an increasing population and demand for water, the City of Ontario made plans to expand the plant’s water treatment capacity from 6 MGD to 10 MGD by constructing additional treatment facilities. It chose WesTech to provide two Trident® package water treatment plants, each with a flow capacity of 2 MGD.

The Trident package water treatment plant uses a two-stage configuration consisting of an up-flow buoyant coarse media roughing clarifier followed by a conventional down-flow fine media filter, providing quality filtration in a small footprint.

| Contaminant | Raw Water | Filtrate |

|---|---|---|

| Turbidity | Range: 2.6-7.5 NTU Average: 5.4 NTU |

Range: 0.02-0.08 NTU Average: 0.03 NTU |

| TOC | Range: 1.2-5.4 mg/L | <1.5 mg/L |

| Iron | Range: 0.05-0.35 mg/L | <0.05 mg/L |

| Manganese | Range: 0.09-0.21 mg/L | <0.01 mg/L |

How It Works

In the Trident, chemically treated raw water enters the tank near the bottom of the buoyant media. The water flows up through the buoyant media, where 80 percent of suspended solids are removed. The water then continues over a weir into a collection trough, where it is distributed into the conventional media filter. The water flows down through the conventional media filter, where the remaining solids are removed. When headloss indicates that cleaning is required, water flush and air scour valves are opened. This causes the buoyant media bed to expand and it is aggressively separated from the solids. Solids are then discharged out the waste pipe. Similarly, when dirty bed headloss is detected in the fine media section, inlet and outlet valves are closed and the air scour valve is opened. Once the air scour cycle is complete, the backwash supply and waste valves are opened, and solids are discharged out the waste pipe. The filter will automatically return to filtration mode once it is cleaned.

| Parameter | Range | Average |

|---|---|---|

| Coagulated dose, poly aluminum chlorohydrate | 5-20 mg/L | 10 mg/L |

| Polymer dose, cationic | 1.5-3.0 mg/L | 1.75 mg/L |

| Potassium permanganate | n/a | <1 mg/L |

| Flush frequency | 6-24 hrs | n/a |

| Backwash frequency | 12-36 hrs | n/a |

| Media | Depth | Effective Size |

|---|---|---|

| MDPE buoyant media | 48 in | 1.7-5.0 mm |

| Anthracite | 18 in | 1.0-1.1 mm |

| Silica sand | 6 in | 0.50-0.60 mm |

| Garnet sand | 6 in | 0.30-0.35 mm |

Successful Installation

Plant operators are pleased with the performance of the Trident. “The City of Ontario has two water treatment plants, one with conventional treatment and one with Trident package plants,” said Larry Lane, plant manager. “I have been very pleased with the performance of the Trident units, especially based on their small footprint.”

With the help of the Trident package treatment plants, the City of Ontario easily increased its maximum flow capacity. The increased capacity allows the plant to better adapt its operations based on seasonal variations in river water quality. Despite these variations, WesTech’s Trident package plant consistently produces quality water that exceeds required water quality expectations.