Clarifier Media Upgrade Decreases Waste Volume

Trident® Package Water Treatment Plant

New Plant Managers, New Improvements

As package treatment plants today are aging, the original managers are moving on, and second or even third-generation managers are taking over plant operations. With the transition of managers, historical knowledge of how the plant has been maintained over the years, including what upgrades have been completed, can be lost. With new managers comes a fresh perspective on the plant’s operations, including updates needed to make way for performance improvements.

The first Trident® packaged treatment system installation in the state of Georgia was a TR-840 two tank system in 1986 at the Baldwin plant. Advancements have been made to the Trident system over the years since these tanks were installed. The current managers of the plant from Engineering Management, Inc. of Lawrenceville, Georgia, understood that the system would benefit from updating to the latest technology of the Trident system.

The Process

The Trident process consists of upflow adsorption clarification followed by mixed media filtration in a packaged treatment system. Coagulant is added prior to entering the Adsorption Clarifier® system. Flocculation and solids capture occur in a bed of buoyant clarifier media contained in the clarifier section.

The clarified water is then filtered through a mixed media bed consisting of anthracite, sand, and garnet. Each layer of filter media has a progressively smaller effective size and increasing specific surface area to form an ever-tightening filter bed. Both the clarifier and filter are periodically cleaned using an air-water flushing system.

Like a filter, as the Adsorption Clarifier system collects solids, headloss develops across the media bed, which initiates a flush cycle. Influent flow is stopped and air is added to scour and turn over the bed, releasing solids. Then, raw water is used to flush these solids to waste and continues to rinse the bed for a period of time. The nature of the waste produced is comprised of the collected solids and any contained in the raw water. The waste volume produced can be significant if frequent flushing occurs, or if the operation is not optimized. Using developed headloss as a trigger to initiate a flush can maximize clarifier run time and minimize waste production.

The Baldwin plant receives its water from the Chattahoochee River. Inlet turbidities to the WTP average 4.3-5.0 NTU. The turbidity has spiked up to 50-60 NTU after a flood event and has been as high as 120 NTU. Color, which impacts chemical dosage and solids production, is not typically measured.

Powder based alum is made into a slurry onsite and used as a coagulant. No polymer is being used. For post treatment, chlorine, soda ash, fluoride, and phosphate are added. The plant operates 18-20 hours per day, based upon demand from the system.

Problem and Recommended Solution

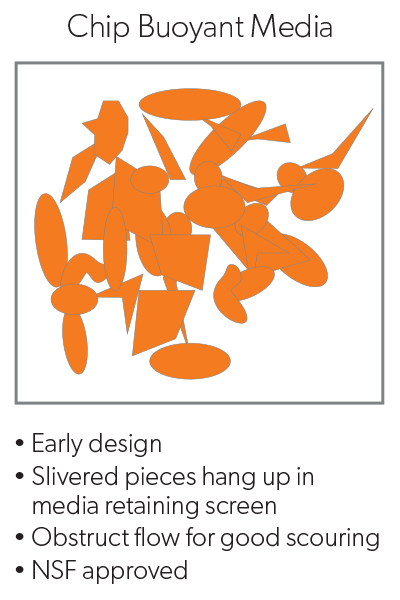

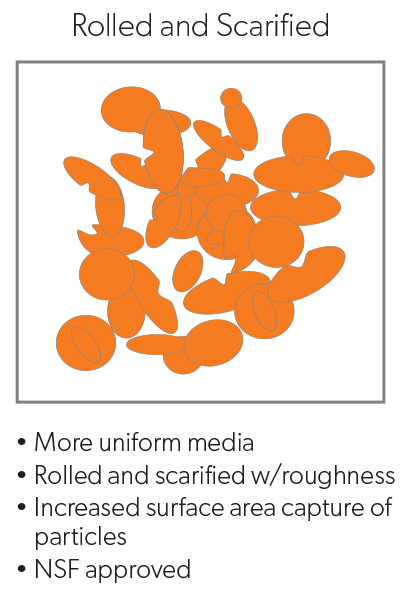

The buoyant clarifier media used when the Trident system was shipped to Baldwin was referred to as a chip grind type. It had sharp pointed pieces that would get stuck in the media retaining screen, restricting flow through the screen. This media type has since been updated with a bead type that is rolled and scarified to greatly improve particulate removal.

The current plant manager could see the potential benefits and decided to replace the old Adsorption Clarifier chip grind type media with the latest media design of rolled and scarified beads. The rolled and scarified beads are used in all Trident package treatment systems installed today. The plan was to perform the upgrades on one unit to see the results and then repeat the upgrades on the second unit if the first unit showed success.

Successful Results

The savings with new media can be two-fold: The reduction in waste volume produced and a savings in time not being offline to do a clarifier flush (18-20 mins), allowing more finished water to be produced (18 mins x 1400 gpm = 25,200 gallons).

Keeping waste volumes low is important for many plant operators because decreased waste volumes correspond to increased treated water production. The less water being used for a clarifier flush or filter backwash, the more water can instead proceed through the treatment process to the finished water supply.

By extending clarifier and filter run lengths, the total wastewater saved can be seen in the table below, which shows a savings of 9,321 gallons per day.

| Waste Volume (gallons) | Frequency (hrs) | Number of Flushes per Day | Total Waste Produced (gallons) | |

|---|---|---|---|---|

| Clarifier flush | 3,500 | 4 | 6 | 21,000 |

| Filter backwash | 7,000 | 38 | 0.63 | 4,421 |

| Waste Volume (gallons) | Frequency (hrs) | Number of Flushes per Day | Total Waste Produced (gallons) | |

|---|---|---|---|---|

| Clarifier flush | 3,500 | 6 | 4 | 14,000 |

| Filter backwash | 7,000 | 80 | 0.3 | 2,100 |

| Total waste water savings (gallons) | 9,321 | |||

Conclusion

Due to the change in clarifier media at the Baldwin water treatment plant, the overall net production of the plant increased and the waste production decreased. The plant is now able to produce more water, and to save 9,321 gallons of waste water each day. By realizing the benefits of relatively simple but necessary upgrades to the Trident system, the current managers are enabling the plant to operate as efficiently as possible.