Paper Mill Drive Retrofit Without Full Bridge Removal

Innovative Installation Approach Saves Customer Time and Money

Problem

WesTech performed an inspection of solids contact clarifiers treating raw process water at a pulp and paper mill. When our mechanical expert identified wear issues on the main bearing of the 25-year-old dual-cage drive, the company accepted our recommendation that it was finally time to replace the drive. The older drive had a high-maintenance chain and sprocket design with many exposed parts and had undergone numerous repairs.

Downtime can affect production and cost larger plants hundreds of thousands of dollars per day in revenue. Expecting that it would take extensive time and work, the company scheduled the drive replacement during the mill’s yearly maintenance shutdown.

One challenge was the unit’s support design for the clarifier bridge. A single support column extended up through the drive unit, and the bridge and entire reaction well were supported by this column. The other challenge was the dome that completely enclosed the clarifier to help protect it from cold winter temperatures. The dome presented a significant obstacle because typical drive replacements require the removal of the entire bridge.

Recommended Solution

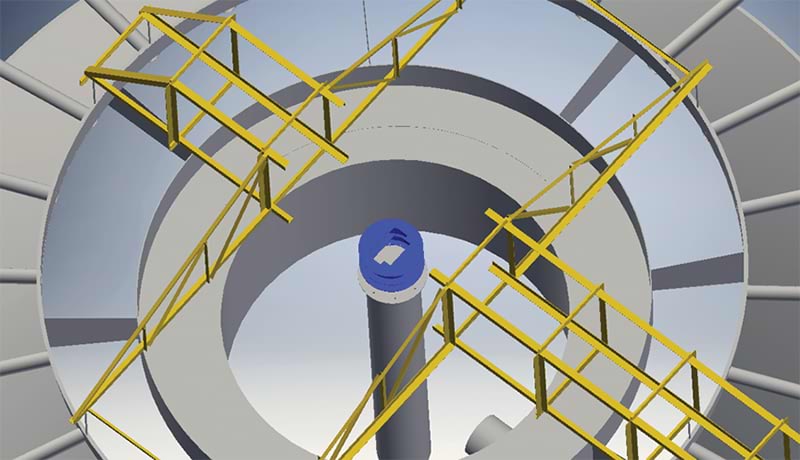

When the company contacted us, our field engineer drove cross-country from Utah (due to pandemic restrictions) to visit the plant and get accurate physical measurements of the existing support structure, drive unit, reaction well, and bridge. Our project engineer then used these measurements to create a three-dimensional (3D) model that enabled WesTech to formulate an innovative installation plan that did not require removing the 150-foot (45.7-meter) clarifier’s entire bridge. This approach would provide significant time and cost savings.

WesTech’s proposal included an 80-inch (2-meter) dual-cage drive unit to replace the mill’s existing drive, along with spare parts and supervision labor for the replacement.

Beyond supplying the equipment, WesTech provided site support resources for the customer, who wanted to self-perform the installation. Before the project officially started, our engineering team reviewed the entire installation procedure with two prospective contractors to make sure they had the information needed to prepare accurate quotes.

The contracting team our customer selected subsequently worked two shifts to limit downtime. Our engineer was on site with the team every step of the way. The first step was to support the bridge and reaction well. Our engineer analyzed stresses on these two structures and determined the best places to support them so the installation team could cut away the T-shaped center support and part of the bridge. A large, 350-ton crane was used to remove the cut-away bridge sections and replace the drive unit. Because the clarifier was bounded by power lines to the north, a river to the south, and a filter building to the west, the crane had to reach over a building and halfway across the clarifier dome to accomplish this.

After the bridge and reaction well were stabilized, the team used the crane to lift the old drive through a hole in the center of the dome and drop in the new drive unit. The retrofit drive bolted seamlessly into the allotted space thanks to our accurate measurements, and the team made necessary on-the-fly adjustments to account for the older drive’s connections. The installation team’s willingness to make speedy adjustments helped keep downtime to a minimum.

As for the drive itself, WesTech’s bolt-in, dual-cage retrofit was constructed with a fully enclosed housing for minimal maintenance. The new retrofit drive included WesTech’s standard drive-unit features such as:

- A cycloidal speed reducer that can withstand higher service loads and shock loads while increasing efficiency to 95 percent

- A precision gear and bearings that have an L-10 service life of over 100 years

- Heavy-duty gear and bearing housings that use a box construction to provide the strongest drive base on the market

- Pinion bearings that eliminate overhung loads on the output bearing of the speed reducer

Results

The customer got its operations back up in less time than it had anticipated. Our modelling expertise and on-site guidance enabled the installation team to accomplish the drive retrofit in just six days, saving the mill an estimated week of labor and downtime. Our faster, innovative, and successful approach to this project satisfied the customer’s needs so well that the company has contracted with us to replace the drive on a different 140-foot (42.7-meter) solids contact clarifier.