Clinton Chooses SuperDisc™ for Phosphorus Removal

Successful Pilot Study Leads to Permanent Solution

Problem

The number of organizations that have imposed phosphorus-related regulations on wastewater treatment plants (WWTPs) continues to grow with our understanding of the environmental damage that excess phosphorus causes.

“Most phosphorus regulations are state- or watershed-driven,” explains Mark Fisher, a Unit Leader for WesTech. “Certain areas are restricted to 1.0 milligrams per liter, others to 0.10 milligrams per liter, and still others to 0.07 milligrams per liter.”

Phosphorus encourages the growth of algae blooms in lakes, ponds, rivers, and streams. Toxins within the algae blooms can irritate human tissues and undermine aquatic life by depleting available oxygen. “When waters start growing a lot of algae, it affects the whole ecosystem,” Fisher observes.

Facing new, more stringent regulations to control the amount of phosphorus it releases to the Nashua River, the Clinton Wastewater Treatment Plant in Clinton, Massachusetts, decided to take a proactive approach.

Analysis

The new regulations under which the plant would soon be operating restricted phosphorus discharge to less than 0.15 milligrams per liter (mg/L) from April through October, and less than 1.0 mg/L from November through March. To meet this regulation, the plant completed a series of pilot studies aimed at determining the most efficient and cost-effective filtration solution. In response to the plant’s call for study participants, WesTech provided a pilot-scale SuperDisc™ unit with a 10 micrometer (μm) polyester cloth filter.

With a flow rate of 24 to 68 gallons per minute (GPM), the SuperDisc pilot reduced influent phosphorus levels measuring from 0.45 to 0.83 mg/L to effluent levels measuring from 0.024 to 0.076 mg/L – well below the WWTP’s treatment goals.

Solution

Based on the SuperDisc’s outstanding pilot performance and cost, the SuperDisc was selected as the plant’s permanent solution for upgrading its phosphorus removal system.

The SuperDisc is a high-rate system that uses multiple filter cassettes. The cassettes are composed of a finely woven polyester filter medium in a strong but lightweight polyester frame. Customers can vary the filter media’s pore size according to the substance they want to filter.

SuperDisc cassettes are arranged along a rotor drum that is housed in either a concrete or stainless-steel tank. Influent flows into the drum’s center. Gravity then feeds it into the interior of each filter cassette. Filtered water flows out from the interior of the cassettes into the tank. When the feed water in the influent chamber rises to a preset level, the drum begins to rotate and an oscillating-arm backwash process cleans the medium, sending accumulated solids into a reject flume inside each filter. From there, the solids are discharged through a discharge pipe.

The filter medium is fused to the frame using a compression-molding process that reduces the risk of contaminants fouling the filtered water via leakage – a common problem with other filter designs.

The SuperDisc backwash process is also much easier on filter media than is the commonly used backwash shoe, which physically scrapes the media. As a result, the SuperDisc’s design increases the medium’s life while maintaining a consistently highquality filtrate.

Implementation

The SuperDisc has a low hydraulic profile, so it operates efficiently in low-head environments. While this makes the SuperDisc an excellent candidate for plants that want to retrofit their filter solutions in an existing space, the Clinton WWTP opted to build a new space to house its phosphorus removal system.

The solution includes three SuperDisc units. Each unit has the capacity to house 30 filter cassettes that are 2.4 meters in diameter. The units currently house 25 cassettes each, enabling the plant to add up to five cassettes per unit to meet increasing demands. Each unit also includes a local control panel that integrates with a single programmable logic controller (PLC), allowing operators to manage units individually or as a group.

As in the pilot study, water from the plant’s secondary clarifiers undergoes chemical conditioning to insure maximum phosphorus removal. The equipment WesTech provided to facilitate this preliminary step includes two flash mixers, four coagulation and flocculation mixers, two polymer feed systems, two coagulant feed pumps, and a WesTech standard chemical-cleaning trolley.

Results

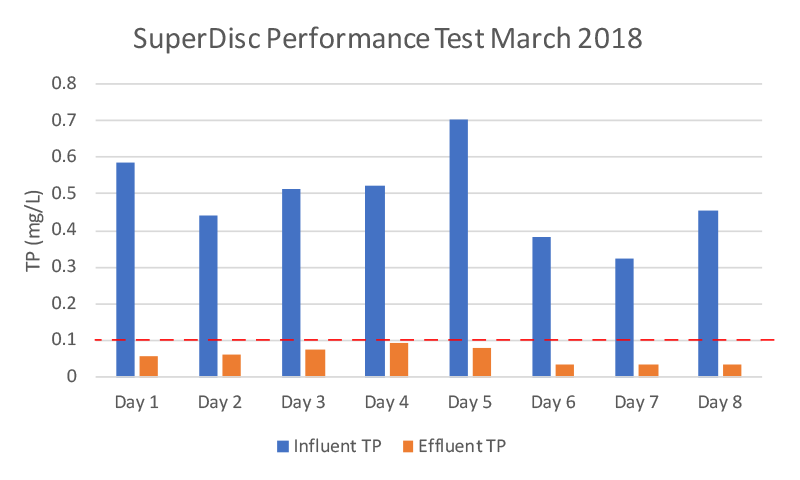

Performance tests indicate that the plant’s SuperDisc system can reduce influent total phosphorus levels that range from approximately 0.3 to 0.7 mg/L to effluent levels that range from 0.03 to 0.1 mg/L.

The plant’s SuperDisc phosphorus treatment system meets the plant’s tertiary wastewater delivery needs, providing backup capacity and the ability to operate without downtime during routine maintenance. The effluent averages less than 0.1 mg/L of phosphorus per month.