Brilliant Water and Sewer District Increases Capacity

Via Vertical Pressure Filters with MULTIWASH®

Problem

Originally built in the 1920s, the Brilliant Water and Sewer District (BWSD) in Brilliant, Ohio, was using two wells to serve a population of 2,100 people through 766 service connections. Faced with the need to increase its average production of potable water from 0.59 million gallons per day (MGD – or 2,233 m3/d) to 1.08 MGD (4,088 m3/d), BWSD sought to add waters from a new well to the two existing wells, Well No. 1 and Well No. 2, which were installed in 1927 and 1945, respectively. BWSD could not operate both wells simultaneously.

Both existing wells were meeting the current primary drinking water standards as set by the U.S. Environmental Protection Agency (EPA) and Ohio EPA. However, adding the third well would trigger an Ohio EPA requirement that would apply to all three wells (Rule 3745-91-09 of the Ohio Administrative Code). Based on this requirement, the Ohio EPA refused BWSD’s new well permit, requiring BWSD to build a new water treatment plant (WTP) to treat source waters from all three wells for manganese. BWSD contracted with W.E. Quicksall and Associates, Inc. of New Philadelphia, Ohio, to help it meet this requirement.

Recommended Solution

The contract proposed developing one new well that would be sized to handle growing demand and constructing a new iron- and manganese-removal WTP with a 1.08 MGD (4,088 m3/d) capacity at a new location. The contract also proposed raw water transmission lines to the new WTP, a finished water transmission line to the existing storage tank, and new sanitary sewer lines that would discharge into existing sanitary sewers.

Planning for the new WTP began in 2015, when the existing plant was not currently meeting manganese-removal requirements. The project’s total cost was $3.6 million, which BWSD financed through grants and community loans. The project took about two years from groundbreaking to completion.

Implementation

The project incorporated state-of-the-art water treatment technology that included three American Society of Mechanical Engineers (ASME) code-compliant downflow vertical pressure filters with manganese dioxide-coated media designed for iron and manganese removal.

The system chemically oxidizes water with sodium hypochlorite prior to filtration. It then introduces the dosed water to the top side of the filter vessel, where the water passes through a bed of filter media to remove unwanted particulate. (BWSD also has provisions for feeding sodium hypochlorite to the high-service pump discharge.)

The filters provide an effective, inexpensive, low-maintenance method of reducing many raw water constituents, including (but not limited to) iron, manganese, turbidity, color, and arsenic.

The WTP disinfects the water with chlorine after filtration and before sending the finished water to the clear well. To adjust water in the clear well for pH and control corrosion, it also feeds caustic soda prior to the clear well. In addition, BWSD uses its dedicated line for finished water to monitor the water’s contact time (CT) with the disinfectant.

All three vertical pressure filter tanks are painted inside and out with NSF-61 compliant paint that is suitable for potable drinking water service.

Each filter includes a MULTIWASH® process that features automatic, simultaneous air and water backwashing. The combined air and water wash provides a vigorous scouring action to clean the media, while specially designed wash trough baffles minimize media loss as the MULTIWASH flushes loosened solids from the media bed. Because operators are not able to easily determine media depth within a closed vessel without physically looking inside (usually by removing the manway), minimizing media loss reduces media-replacement and downtime costs.

The MULTIWASH cleaning process prevents both chemical and biological media fouling and eliminates expensive chemical cleaning and frequent media replacement. This reduces long-term operational costs and improves filtration efficiency. The vessels’ configuration allows the plant to perform backwashing with in-service filters, which eliminates the need for backwash supply pumps, tanks, and valves.

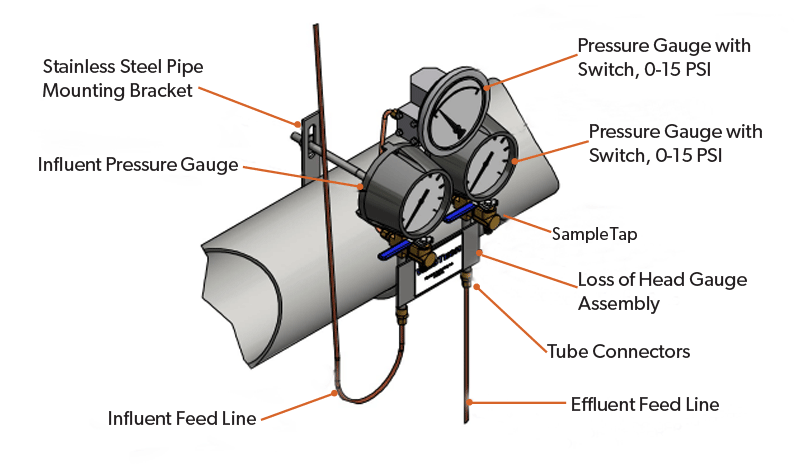

BWSD can initiate backwashing either manually or automatically using electrically actuated valves. In automatic mode, backwash can occur when the filter system reaches a terminal headloss across the bed. (Gauges and pressure switches monitor headloss across the filter. The system can accommodate one in-service filter backwash at a time.) Operators can also use the automatic mode to schedule backwashing at specific times.

Finally, the new WTP includes an Allen Bradley programmable logic controller (PLC) and supervisory control and data acquisition (SCADA) system, which delivers real-time graphic visual displays and generates reports.

Results

The new drinking water treatment plant provides a maximum design capacity of 1.08 MGD (4,088 m3/d) to serve BWSD’s local customers and assorted businesses. The plant’s design capacity will also meet the growing community’s needs for the foreseeable future.

The plant now has a capacity of 750 gallons (2.8 m3) per minute running all three filters. It currently pumps water from the two cells of its on-site clear well to one of two storage tanks: a 183,000-gallon (693 m3) tank owned by BWSD and a 240,000-gallon (908 m3) tank owned by Jefferson county. Each of the plant’s clear well cells holds 24,100 gallons (91 m3).

In addition to meeting BWSD’s capacity goals, the new WTP meets state and federal drinking water requirements. BWSD operators conduct monthly sampling measurements to ensure that it is meeting Ohio’s stricter manganese removal requirements. Testing indicates that iron and manganese are currently at non-detectable levels in BWSD’s finished water.