Retrofitting Membrane Filtration

Ultrafiltration System

Production Problem

The Dekalb-Jackson Water Treatment Plant opened in 2007. Previously, the counties of Jackson and Dekalb provided water to residents by purchasing it from neighboring water districts. With increasing populations in Jackson and Dekalb counties, it was necessary to construct a facility to produce their own water supply by drawing from the Tennessee River. Raw water has organics, which affect taste and odor, and turbidity spikes up to 30 NTU.

Membrane technology was originally selected because it provides a physical barrier against contaminants. However, the current membrane system did not meet expectations. Since start-up, operators faced problems with excessive fiber breaks and meeting production demands.

In addition to excessive fiber breaks, the membrane system experienced frequent fouling despite pretreatment. To reduce fouling, frequent chemical cleans were necessary. These cleans consumed time and made it difficult to meet system demands. After years of altering operational and cleaning procedures in unsuccessful attempts to achieve production goals, Dekalb-Jackson Water Supply District was in need of a permanent solution.

Selecting a Solution

To remedy the situation, Dekalb-Jackson worked with Greenhill Engineering and WesTech to determine the best approach to replacing the existing membrane system. As part of the evaluation, WesTech performed an eight (8) month long pilot study with a membrane filtration system incorporating Toray membranes.

The pilot study demonstrated consistent production of high quality filtrate under a variety of operating conditions with regular chemical cleans limited to once every 30 days. There were no fiber breaks for the duration of the pilot, nor problems with fouling, regardless of flux rate. After successfully completing the pilot study, WesTech was able to accurately design an ultrafiltration system to retrofit the existing membrane system.

| Flow | Range: 20.5-53.8 gpm Average: 27.4 gpm |

|---|---|

| TMP | Range: 6.1-28 psi Average: 12.5 psi |

| Normalized flux | Range: 45-90 gfd Average: 60 gfd |

| Outlet turbidity | Average: 0.012 NTU |

| Recovery | Range: 97.7%-98.7% Average: 98.1% |

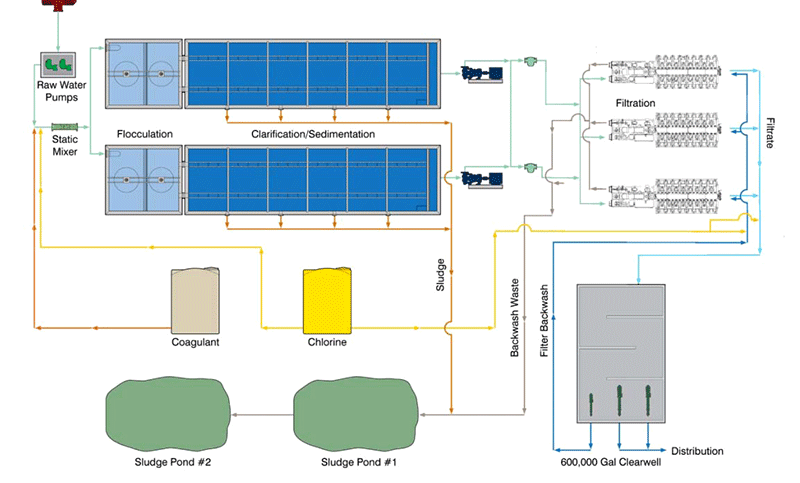

At the Dekalb-Jackson Water Treatment Plant, water is drawn from the river and pumped to one of two package treatment plants, previously provided by WesTech. Treated water from the package plants is then pumped to the membrane systems, and from the clearwell is sent to distribution.

WesTech’s Ultrafiltration Membrane System, featuring Toray membrane modules, has a nominal pore size of 0.01 µm. It provides exceptional removal of pathogen and particulate matter, achieving greater than 4.0 log removal of cryptosporidium and giardia, and greater than 1.5 removal of viruses.

Installation

WesTech worked closely with the plant, engineer, and contractor, making detailed plans to minimize time the plant was offline during retrofit installation. With careful design and planning, WesTech was able to remove the old system and install the new system in a way that allowed the plant to be offline for less than a day.

Performance

The new membrane system performs substantially better than the previous system. The new WesTech ultrafiltration system has improved recovery from 91.7 percent to 96.9 percent, increased flux by 54 percent, and has reduced system energy consumption through a 60 percent decrease in average TMP. Chemical cleaning frequency has decreased from once every 15 days to once every 30 or more days, further reducing operating cost and allowing the plant more production time.

| Previous System | Retrofit System | |

|---|---|---|

| System | 4 trains 16 modules per train |

3 trains 32 modules per train |

| Footprint | 15' 10 ⅝" x 4' 1 ⅛" | 17' 11" x 6' 4" |

| Membrane surface area | 1,227.1 ft2 per module | 775 ft2 per module |

| Average system flow | 1.663 MGD | 2.255 MGD |

| Average flux rate | 23.62 gfd | 36.35 gfd |

| Average TMP | 13.50 psi | 5.39 psi |

| Filtrate turbidity | Average: 0.026 NTU <0.1 NTU 99.4% <1.4 NTU 100% |

Average: 0.0091 NTU <0.1 NTU 99.95% <0.238 NTU 100% |

| Recovery | Average: 91.7% | Average: 96.9% |

| Quantity | 96 modules |

|---|---|

| Material | PVDF |

| Membrane area per module | 775 ft2 |

| Flux @ design temp | 8°C |

| N. Flux at design temp (20°C) | 65.32 gfd |

| Design flow | 3.0 MGD |

| Estimated water recovery | 95.9% |

Customer Satisfaction

Plant managers and operators are pleased with WesTech’s superior service and quick work in retrofitting the plant. Tommy Bryant, manager at the Dekalb-Jackson Water Treatment Plant stated:

“We feel fortunate, given the events that have transpired at our facility, to have chosen a company with the integrity that WesTech has shown, to be partnered with.”

Thanks to WesTech’s superior service, residents of Dekalb and Jackson counties have clean, high quality water from reliable equipment.