Vacuum Filtration Improves Fried Food Operations

Drum Filter Maintains FFAs in Safe Range

Background

Hot oil filtration is important in any food processing area that uses fryer oil to create the finished product, such as convenience foods like chicken and french fries, snack foods like tortilla chips, and elements of ready-made meals. The quality of a commercially fried food product can depend on many things, but most importantly, the quality of the oil it is fried in. With good oil, food tastes better, is healthier, has an improved shelf life, and the oil lasts longer.

Of the three key ways that oil quality is evaluated – the crumbs, the color, and the level of free fatty acids (FFAs) – the color and crumbs are more often addressed by common filtration processes. However, these solutions do not often address a crucial issue: the level of FFAs in the oil, a key indicator of the overall oil quality and contributor to the oil’s useful life.

Problem

When frying takes place, FFAs form due to the presence of moisture in the foods that remain in the oil. A normal range is 0.5-0.8 percent FFA. If water is not driven out of the food fast enough through frying, the FFA content grows quickly. Frying oil begins smoking at a lower temperature when FFA is higher, and the character of the food is compromised.

A customer with a large poultry processing plant in the Southern United States was building a new plant and wanted to incorporate a filtration system to keep from having to discard spent, high FFA oil. To keep the oil quality high enough for continued reuse, the FFAs needed to remain below 1.5 ppm.

Analysis of Alternatives

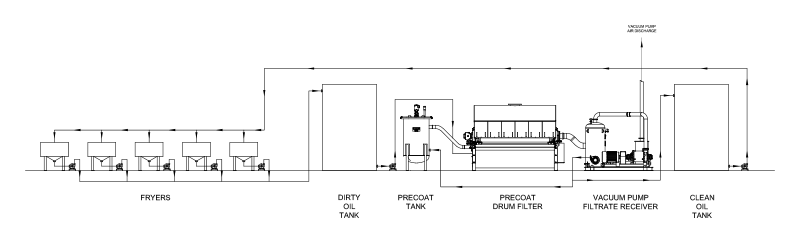

In a fried food processing plant, an oil filtration system can remove the solids and more while integrating smoothly into the industrial frying operation, which often includes the frying unit, a heat exchanger to heat the frying oil, a circulation pump, tanks for dirty and clean oil, a control system, and the oil filtration equipment.

Conventional filtration uses gravity, pressure, or vacuum pressure to create a driving force necessary for the liquid to pass through different kinds of filters – such as perforated plates, cellulose filter papers, or glass fiber filters – or granular material, such as sand or anthracite.

Other, less common mechanical methods include membrane filters that rely on media with much smaller pores and temperature limited operations.

Many of these systems require high maintenance and significant periods of downtime. Filter paper systems, in particular, require frequent downtime as the paper gets saturated with contaminants and needs to be changed, sometimes multiple times a day. They also have capacity issues, as ultrafines can limit filtration throughput.

Recommended Solution

The customer was considering a filter paper technology but recognized it could not meet its FFA requirement, so the customer contracted with WesTech for a vacuum drum filter to apply precoat filtration to its hot oil frying filtration needs. With decades of experience in filtration for the water industry, WesTech was able to adapt its outstanding water filtration technology to the hot oil filtration needed for this food processing plant.

The customer targeted removal of suspended solids and reduction of FFAs to a level of 0.5 - 1.5 ppm. If the FFAs were higher than 1.5 ppm, then a scorched taste and smell would become apparent. It is difficult to achieve an FFA less than 0.5 ppm.

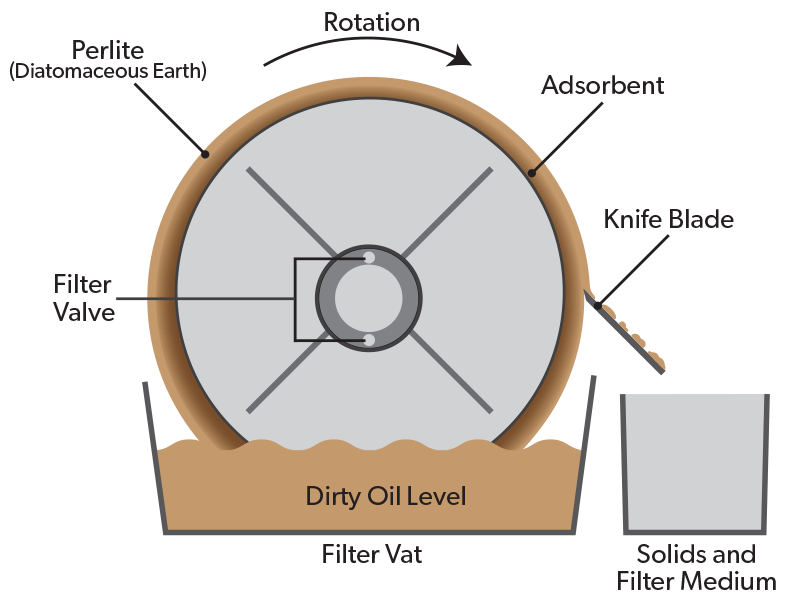

The vacuum drum filter has a porous, screened drum cylinder, ranging in size from 18 inches to more than 8 feet in diameter. The outside surface is precoated with an FFA absorbent and a perlite diatomaceous earth media. The hot oil is sucked by the vacuum through the precoat bed on the drum’s surface to the inside drum piping and sent on its way to the clean oil tank.

There are two processes of filtration as the oil passes through the filtration bed on the drum. First, the suspended solids are captured on the outside of the drum. Next, the clean oil passes through the absorbent portion of the drum coating, where the soluble FFAs are absorbed. When the drum turns, it passes an advancing knife that cuts off the particulate solids and a very thin layer of the filter media, part of a sacrificial filtration media bed. This allows a fresh filter surface to be re-immersed in the dirty oil as the drum continues to rotate.

Implementation

The filter was simple to install in the production line, and it easily adapted to filtering high temperature oil. WesTech adapted the technology, usually used for wastewater, for use with hot oil. The installation required the addition of high temperature equipment safeguards, to ensure the critical oil quality and allow for redundant controls.

WesTech’s vacuum drum filtration was a good choice for this plant as it introduced a one-step operation to clean the oil, both removing the FFAs and addressing the oil’s color and crumbs. Using this system, the company could recycle its oil nearly indefinitely, with make-up required only for the product drag-out, thus improving the economic value stream.

Conclusion

When oil is effectively filtered from a commercial deep fryer, it improves the profitability of the food processing and the quality of the food to the consumer.

Commercial food processors who produce fried food can sell used fryer oil and recover a little money from their outlay cost that way. However, it is more economical to sell drag out oil with the high-value fried food.

WesTech’s Vacuum Drum Filter is an option that includes both mechanical and chemical processes with demonstrated success in the hot oil filtration market. At this Southern U.S. processing plant, the FFA level was tested on a sample a few months after installation, and the results showed the oil in the clean range, a win for processors and consumers.