Adsorption Clarifier® Increases Plant’s Hydraulic Capacity

Miners Ranch Water Treatment Plant

Problem

To meet future growth in the Oroville area, South Feather Water and Power Agency (SFWPA) needed to expand the hydraulic capacity of its Miners Ranch Water Treatment Plant (WTP) from 15 MGD (2366 m3/h) to 21 MGD (3312 m3/h). The challenge was this: The plant, which SFWPA opened in 1980, had limited space for installing new unit processes and equipment. SFWPA commissioned Stantec Consulting Services, Inc., to examine the methods by which the plant might meet its 21 MGD (3312 m3/h) goal and to develop plans and specifications for this design-build project.

Analysis of Alternatives

Stantec’s study determined that there was sufficient water storage in several reservoirs to meet the Oroville area’s future demand. The firm also noted that the plant had two trains to treat the raw water, which currently comes from Little Grass Valley Reservoir. The raw water’s average turbidity of 0.4 NTU can increase from 10 NTU to 50 NTU, depending on rain events. The first train was a direct filtration system with an original design capacity of 12 MGD (1893 m3/h). The second was a conventional system with flocculation, sedimentation, and filtration. Design capacity for this system was up to 3 MGD (473 m3/h). The actual total capacity of the plant was 14.5 MGD (2287 m3/h).

To increase the plant’s capacity, Stantec reviewed several treatment processes – including pretreatment with conventional systems, ballasted flocculation, inclined plates, and the WesTech Adsorption Clarifier® system.

Recommended Solution

Based upon Stantec’s review and evaluation, it selected WesTech’s Adsorption Clarifier process as the best pretreatment solution because of the system’s smaller footprint, lower operating costs, lower capital costs, and ease of maintenance.

The Adsorption Clarifier is a high-rate clarification system that you can use as a standalone pretreatment clarifier to filters or in a packaged system such as the WesTech Trident® family of clarification plants. It is designed to replace pretreatment options such as solids contact units or flocculation and settling equipment. Its hydraulic loading rate is 10 gpm/ft2 (24 m/h) and its retention time is approximately 3-5 minutes. The Adsorption Clarifier is the highest-rated clarifier in the market today – a big advantage when dealing with finite available space.

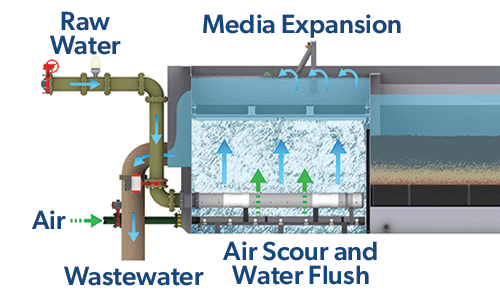

The Adsorption Clarifier uses an upflow-system design wherein buoyant media creates a tortuous path through which the influent must snake its way upward. A media retention screen prevents media loss. The media itself provides flocculation, capturing the floc within the void spaces or removing it via adsorption. This process replaces clarification as well as flocculation. The goal is to produce a “microfloc” that is removed in the buoyant media, as opposed to a settalable floc.

WesTech’s Adsorption Clarifiers typically achieve solids removal of 70-90 percent of inlet water turbidity without a mechanical sludge-removal process. Instead, solids that collect within the buoyant media are removed via flushing. This process consists of air scouring to expand the media, allowing the void space to increase, and a water wash to flush out the accumulated solids within the media. The waste is collected in a wash trough for disposal.

Implementation

The plant installed six Adsorption Clarifier units in new concrete basins in the fall, with start-up the following spring. Each Adsorption Clarifier cell is 245 ft2 (22.8 m2), with a total installation size of 1470 ft2 (136.6 m2). Together, the units provide pretreatment for the entire plant. This installation is less than 10 percent of the size that a conventional system – such as a solids contact clarifier – might occupy, and less than 30 percent of the size a ballasted flocculation system would require.

Results

The new pretreatment system at Miners Ranch enables the plant to provide 21 MGD (3312 m3/h) of clean water – a figure that meets expected demand over the next 30 years. The filter effluent averages 0.02-0.05 NTU. The Adsorption Clarifier removes 70 percent of the unit inlet turbidity, after addition of the coagulant, allowing the filters to backwash based upon throughput with minimal headloss buildup. The run lengths between flushes range from 10-18 hours, depending upon the water quality.

John Shipman, the plant superintendent, affirms that the Adsorption Clarifiers fit in the limited space that was available better than a conventional system would have. Overall, Shipman says he is “really impressed, and happy, with the Adsorption Clarifiers.”