Excellent Clarity Achieved With Solids CONTACT CLARIFIER™

Background

Since the early 1970s, the Columbine Water Treatment Plant (WTP) in Thornton, Colorado, had treated a surface water supply using hybrid flocculating clarifiers and conventional granular media filters. In 2002, the City of Thornton and its consulting engineer, Burns & McDonnell, set about expanding the capacity of the WTP from 28 to 56 MGD and replacing the granular media filters with ultrafiltration (UF) membranes. They wanted to use the existing granular media filter boxes and piping gallery for the UF membranes and the existing four 65-ft-diameter flocculating clarifier basins for pretreatment clarification.

The existing clarifier mechanisms were quite difficult to operate, requiring many adjustments when changing the WTP flow rate. The city had installed 2-ft-deep tube settlers in the clarifiers to improve overflow clarity. The clarifier-rated hydraulic loading was 1.72 gpm/ft2, or about 7 MGD per basin. The city conducted a hydraulic loading stress test by operating one of the clarifiers at 9 to 11.5 MGD, where the launders flooded. The overflow clarity was acceptable at less than about 2 NTU for this abbreviated test.

Equipment Evaluation

Burns & McDonnell evaluated various ways of high rating the clarifiers. It considered using lamellas or deep (4 ft) tube settlers and enhanced flocculation using a true solids contact clarifier, which would have to operate at a design hydraulic loading of 3.74 gpm/ft2 just under the outlet launders. WesTech contributed the knowledge of how to operate such high-rate solids contact clarifiers, based on solids inventory control and basic slurry settling characteristics. Burns & McDonnell’s specifications required a seven-day continuous performance test be conducted at the design flow rate of 15 MGD per basin to demonstrate that the following clarity could be produced: less than 3 NTU 95 percent of the time, and 3 NTU maximum daily average.

Performance Test

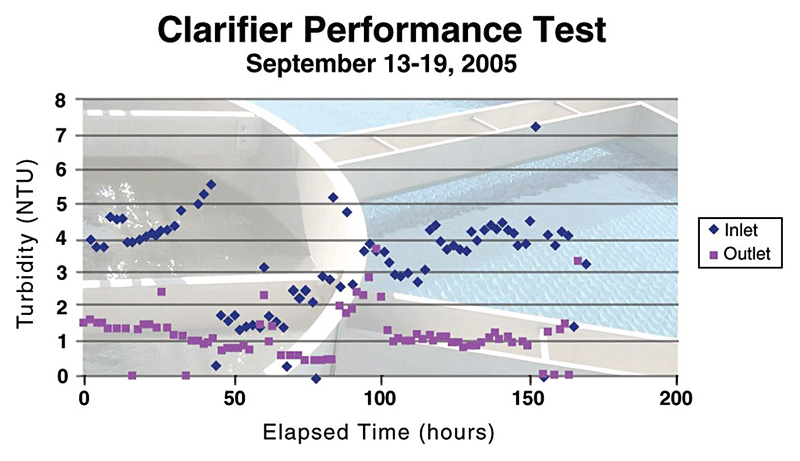

The performance test was conducted during the period of September 13-19, 2005. Columbine WTP personnel operated one of the four units and captured all operating conditions and performance data.

The range of average daily flows was 13.1 to 15.7 MGD with an overall average of 14.7 MGD. This flow resulted in an average hydraulic loading of 3.66 gpm/ft2 and a flocculation detention time of 12 minutes. The flocculation mixing energy was in the range of 10 to 40 S-1 G value. The raw water temperature ranged from 70 to 74 °F and the average chemical feeds were 15 mg/L of FeCl3, 10 mg/L of PAC, 4.7 mg/L of NaOH, and 1.7 mg/L of KMnO4, consistent with routine WTP operations. The average daily raw water turbidity ranged from 1.72 to 6.87 NTU with an overall average of 3.90 NTU, typically a difficult-to-treat low level of raw water turbidity.

The graph below shows the 78 turbidity results compiled during the seven-day performance test.

Test Results

The range of average daily outlet turbidity was 0.93 to 1.50 NTU with an overall average of 1.19 NTU, well below the 3 NTU level required. Seventy-six of 78 NTU measurements, or 97.4 percent, were below the specified 3 NTU requirement.

These excellent clarification results were achieved even though the solids inventory control of the test solids CONTACT CLARIFIER™ was less than stellar.

The day before the performance test was started, the sludge blanket was allowed to rise into the 4-ft-deep tube settlers, resulting in noticeable floc clouds above the tubes.

A major solids inventory reduction, estimated to be about 80 percent, was made, resulting in no solids being present at the minimum control elevation/sample tap (1.25 feet above the bottom of the side wall) for the first 24 hours of the performance test. During the performance test, there were 20 of 38 samples within the desired range of 5 to 15 percent volume at 10 minutes of settling, and 18 of 38 samples below or above (as high as 22 percent) the desired range.

Of concern at the time was the fact that the sludge blanket was allowed to rise to within 1.2 ft of the bottom of the tube settlers (sample tap #4) for 24 out of 38 solids concentration samples, with six of those samples reporting 20 to 25 percent volume at 10 minutes. There were only 10 of 38 samples that had no solids present.

Current Status

The observation that excellent clarity was achieved with widely varying solids inventory, and that the sludge blanket must have existed within the tube settlers on many occasions, speaks volumes about the effectiveness of the 4-ft-deep tube settlers and the robustness of the CONTACT CLARIFIER operation. One of the Columbine WTP operators, who spent three decades operating the old hybrid flocculating clarifiers, mentioned that the new CONTACT CLARIFIER was much simpler to operate and was using considerably less FeCl3 coagulant than the old units.