RapiSand™ Doubles Treatment Capacity for a Lower Cost at Arizona Water Treatment Plant

Challenge

The population is expanding in the town of Gilbert, Arizona, and the nearby City of Chandler. The Santan Vista Water Treatment Plant (WTP) provides potable water for these growing municipalities, so the plant needed to expand as well, doubling its capacity. In 2009, when it was commissioned, the Santan Vista WTP was designed to treat 24 million gallons per day (MGD) of drinking water from the Central Arizona Project’s Colorado River watershed. This water source requires removal of some organic carbon and suspended solids. To continue providing dependable drinking water to the growing population, the plant needed additional equipment to increase its capacity to 48 MGD.

Analysis of Alternatives

The original construction plan of the Santan Vista WTP included two ballasted flocculation clarification trains, each with a design capacity of 12 MGD. The plant selected this technology because of the comparatively small footprint, capacity to treat large flow rates, and impressive performance characteristics. The technology had also proven to be an effective water treatment method at other plants in the region. When it came time to upgrade, Santan Vista chose to continue with ballasted flocculation, but the plant was interested in evaluating other equipment suppliers.

Soon after the original plant construction, WesTech Engineering had developed, introduced, and piloted its own ballasted flocculation system called RapiSand™. Based on the company’s experience and competitive pricing in water treatment and ballasted flocculation, WesTech was considered for the project, along with the original equipment supplier.

Recommended Solution

After a careful evaluation of total value, the Santan Vista WTP and the project team selected the WesTech RapiSand for the plant’s expansion. WesTech provided an attractive offering with its performance warranty, in-house electrical expertise, ability to match existing equipment like mixers and pumps, and quick response to questions and needs.

The RapiSand ballasted flocculation is a high-rate sedimentation process that decreases time required for flocculation and enhances settling rates. This technology gains an advantage by mixing fine silica sand with the flocculant to facilitate greater flocculation size and increase settling velocity. By using sand in the sedimentation process, high flow rates can be treated in a small footprint. The RapiSand provides high performance clarification with a space savings of up to 90 percent when compared to the size of conventional treatment. At Santan Vista, ballasted flocculation is followed by ozonation, media filtration, and chlorine disinfection. This facility also has the ability to recycle filter backwash and clarified underflow using a WesTech SuperSettler™ lamella-type plate clarifier.

Implementation

For WesTech, the first step of the project included a complete evaluation and upgrade of the existing control panels and programming. As the Santan Vista WTP doubled in size, including the installation of two RapiSand trains, the existing controls also needed to be expanded and modernized. Existing controls were upgraded to include redundant programmable controllers, ethernet communication between all components in the system, remote operation, and new programming to handle the additional equipment. This major undertaking required two phases to create as little interuption as possible, while allowing a smooth transition into the expansion.

Phase one included a pre-installation test of the upgraded controls, communications, and additional inputs and outputs at the WesTech assembly and testing facility in Salt Lake City, Utah. WesTech controls experts then visited the plant to install these upgrades during a scheduled shut-down of the plant. The intention for the controls upgrade was to have the existing system operate exactly as before, eliminating any confusion for the operators. When the plant came back online, the upgraded controls worked flawlessly, and the original equipment functioned as before.

Phase two involved upgrading the operation interface and the programming of the new RapiSand trains with the upgraded controls, while maintaining a similar “feel” for the plant. The RapiSand electrical equipment installation met the construction schedule thanks to a team effort with Santan Vista WTP, Black & Veatch, and Sundt Construction.

Results

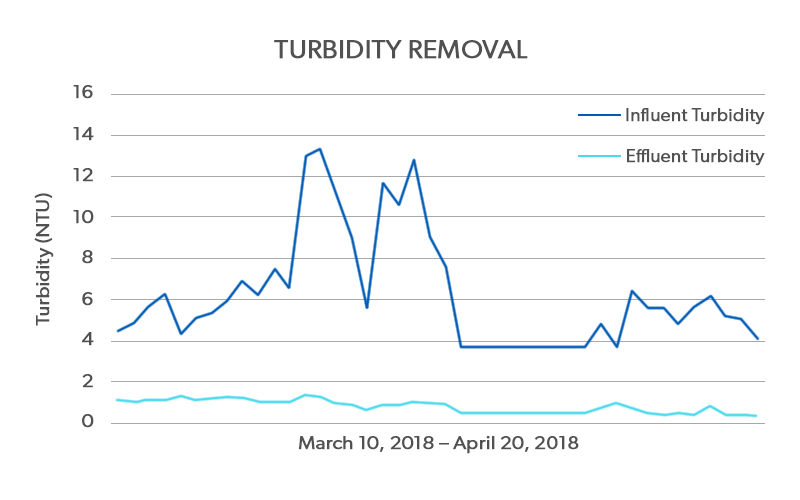

Within hours of start-up, the RapiSand outlet water quality matched the quality of the two existing ballasted flocculation trains at Santan Vista. Over the first month of treatment and data collection, the WesTech RapiSand successfully reduced turbidity in all conditions and yielded a lower, more consistent turbidity range in the effluent water quality (between 0.3 and 1.4 NTU). The final testing and start-up period progressed smoothly, which helped make the Santan Vista WTP upgrade the 2018 AZ Water Treatment Plant Project of the Year for large facilities.

| Average Effluent April 1 Thru 20 | |

|---|---|

| WesTech RapiSand | 0.506 NTU |

| Original ballasted flocculation | 0.779 NTU |

The RapiSand fulfilled all expectations for high-rate clarification at a fraction of the cost of the original ballasted flocculation trains, functioning effectively in coordination with the other equipment in the water treatment plant to provide a higher output of clean water. The success of RapiSand at Santan Vista WTP has led to many more full-scale installations, mobile treatment plant rentals, and requests for WesTech’s pilot plant trailer.