Expansion Made Easy With Adsorption Clarifier®

California WTP Retrofits Existing Concrete Basins

Problem

Holding water rights that date back to California’s Gold Rush days, the El Dorado Hills Irrigation District (EID) currently serves approximately 128,000 residents in California’s El Dorado County. This historic organization owns and operates several water and wastewater treatment plants in the county, including the El Dorado Hills Water Treatment Plant (WTP), which treats surface water pumped from Folsom Lake. The plant has undergone many changes over the years to meet a steadily increasing population. For example, in 1993, the plant installed two Trident® package water treatment plants, which replaced equipment originally installed in 1960. Pleased with the operation of the Trident technology, the plant installed another two units in 1995.

When demand increased further, the plant had no available space for additional Trident units. The need to double the plant’s capacity from 8 to 16 MGD (30-60 Ml/d), coupled with the lack of space, posed a significant challenge for EID.

Recommended Solution

The solution to EID’s capacity vs. space dilemma came by way of innovative thinking on the part of our engineering experts, who suggested converting unused concrete basins at the plant into a concrete version of Adsorption Clarifier® units and concrete media filters.

The Adsorption Clarifier is a high-rate clarification system that can be used as a stand-alone pretreatment clarifier to filters or within a packaged system such as the Trident. With a standard hydraulic loading rate of 10 gpm/ft2 (24 m/h), the Adsorption Clarifier is designed to replace pretreatment equipment such as solids contact units or flocculation and settling equipment. The advantage of this system is a smaller footprint, lower profile, and a cost savings to the owner.

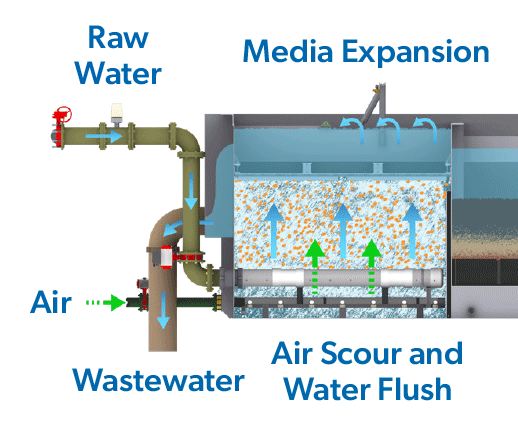

The Adsorption Clarifier uses buoyant media in an upflow system design. The water travels upward through the media and the floc that is produced is captured within the void spaces of the media and adsorbed onto the media. This process, which is called “contact flocculation,” replaces conventional flocculation and clarification. The goal is to produce a “microfloc” that is removed in the buoyant media, as opposed to a settleable floc. A retention screen atop the unit prevents media loss.

The Adsorption Clarifier achieves significant solids removal – typically 70-90 percent of inlet water turbidity. It does not require mechanical sludge removal. Solids collected within the buoyant media are removed via flushing, which consists of air scouring to expand the buoyant media and allow void spaces to increase, combined with a raw water wash to flush the collected solids out of the media. The waste is collected in a wash trough and directed to waste.

The second stage of the plant’s system included converting another concrete basin into gravity filters containing mixed media (also referred to as multimedia or tri-media). The hydraulic loading rate of the filter section is 5 gpm/ft2 (12 m/h). In general, this process has demonstrated the ability to achieve filter effluent turbidity of <0.1 NTU in full-scale applications, with many plants – including the El Dorado Hills plant – achieving effluent turbidity in the range of 0.02 to 0.05 NTU.

Combined, the two processes have demonstrated the ability to achieve 99.9 percent turbidity removal with 3 log removal of 5-15 micron-sized particles.

Results

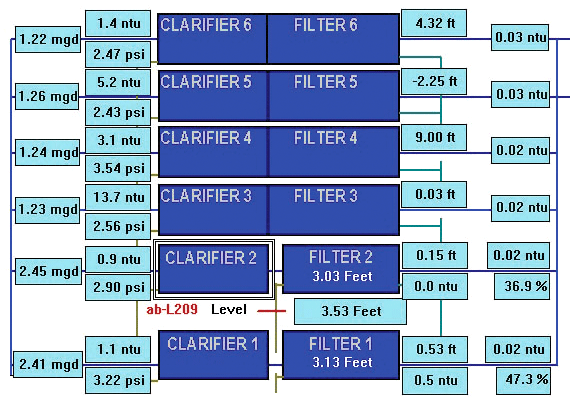

Using the existing basins and the Adsorption Clarifier process allowed the plant to double its capacity without making major modifications to the facility or purchasing additional land for new equipment. According to EID’s data (see the chart), the new systems produce effluent turbidity at or below 0.03 NTU and greater than 3 log removal of 5-15 micron-sized particles.

The plant operators continue to be very pleased with the performance of the original Trident systems and the Adsorption Clarifiers. Bill Peterson, the plant’s chief operator, prefers this technology over conventional treatment.