Pilot Study Improves Mine Water Treatment

CONTRAFAST® High-Rate Thickener Clarifier

Problem

A Peruvian mining company requested a proposal for testing updated water treatment technologies at a mine located on the sides of a deep valley in northern Peru. The company wanted to evaluate the efficiency and effectiveness of newer technologies that could help it reduce high levels of arsenic and total suspended solids (TSS) in its mine runoff. Groundwater seeps into the operation’s mine shafts and flows out of the mine through natural openings, carrying with it levels of arsenic that sometimes exceed 500 milligrams per liter (mg/L) and turbidity that can exceed 100 NTU.

To comply with Peruvian regulations, the mine must have an effective and reliable process for treating this water to levels of arsenic that are lower than 0.08 mg/L and TSS levels below 24 mg/L before releasing the runoff into a nearby stream, which flows into the headwaters of the Amazon River.

Analysis of Alternatives

The mining operation’s current treatment consists of adding an anionic polymer and ferric chloride to the runoff before diverting it into one of four holding ponds, in which the reactive chemistry coagulates the arsenic and suspended solids in a floc that settles to the bottom. The sludge from these ponds is sent to an evaporation pond. When the sludge has dried to a cake consistency, the mine disposes of it in a lined fill site.

Additional objectives for this project were to evaluate ferric chloride and polymer dosing rates as well as the proposed technology’s performance at full-scale design and at various hydraulic loading rates. The company also wanted to determine the tested technology’s net production.

The company chose WesTech Engineering for its testing project based on WesTech’s proposal and procedures.

Recommended Solution

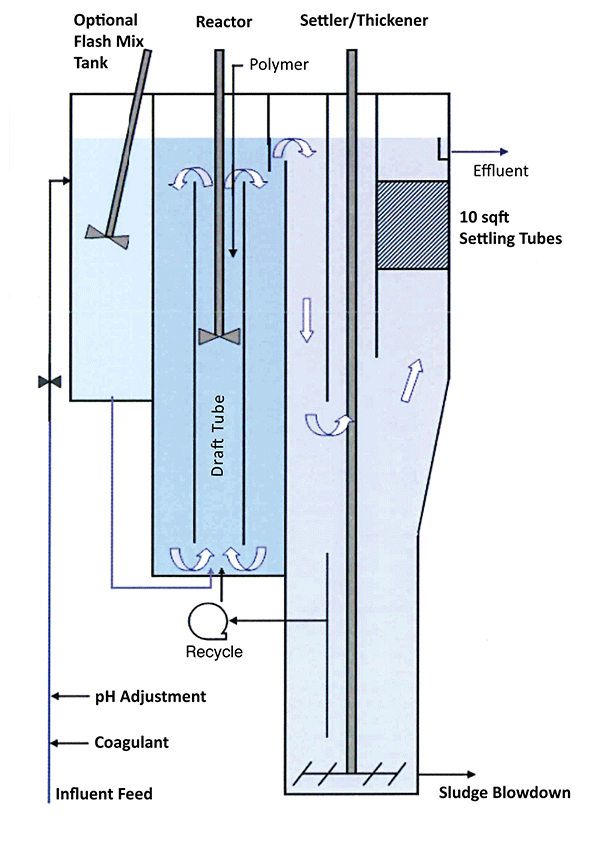

WesTech engineers recommended a CONTRAFAST® pilot plant to demonstrate how the mining company could improve both the efficiency and effectiveness of its water-treatment process using CONTRAFAST.

CONTRAFAST is high-rate clarifier and softener technology that combines clarification and sludge thickening in a single operation. It has a footprint that is 25 to 50 percent smaller than that of a conventional clarifier alone, making it a good choice in locations where space is an issue. It can run at rise rates that exceed 23 L/min/0.1 m2 (6 gpm/ft2). This is over four times the rate typically used for conventional clarifiers. CONTRAFAST also efficiently produces sludge with more than 10 percent solids by weight and can handle the mine’s flow rates, which range from 114 to 379 L/min per 0.1 m2 – 30-100 gpm/ft2.

Implementation

A CONTRAFAST pilot unit was used for 19 days to evaluate the technology’s effectiveness and hydraulic performance. The study also determined the optimum ferric chloride dosage for arsenic removal and identified optimal chemical pretreatment. In addition, it provided sludge characterization data. WesTech engineers added instrumentation – including flow meters, a pH sensor, and chemical test strips – to the unit to facilitate water-quality control.

For the pilot study, WesTech engineers diverted ground water past the mining operation’s ponds. Influent was pretreated with ferric chloride for arsenic removal and anionic polyacrylamide to assist rapid settling. The pretreated influent then entered the CONTRAFAST Flash Mix Tank.

After flash mixing, the slurry entered a center draft tube for high-rate downflow recirculation, followed by an internal reactor section for upflow recirculation. After passing through a downflow transfer zone, the influent entered the CONTRAFAST settler/thickener area, which includes a 1 m2 (10 ft2) area containing settling tubes that are set at a 60-degree angle.

The treated effluent flowed from the top of the CONTRAFAST tank. An external sludge recirculation pump returned 10 percent of the conditioned solids back into the raw flow stream and a scraper mechanism diverted the remaining solids to a center sump with intermittent blowdown.

WesTech engineers analyzed and properly adjusted the chemical feed during optimization tests to achieve required arsenic removal and TSS levels. Ferric chloride was also analyzed and adjusted based on water condition to determine an optimal dosage rate.

Results

The WesTech CONTRAFAST proved to be an excellent solution to treat water under various influent flow rates and turbidity levels. The CONTRAFAST met or exceeded the protocol outlined by the mine; it reduced arsenic content to an average of 0.0459 mg/L and clarified effluent TSS to levels that were consistently below 5.33 mg/L. The hydraulic loading rate was up to 38.6 L/min per 0.1 m2 (10.2 gpm/ft2)

The results also indicated that an automated control system would allow for automatic adjustment of the solids recirculation rate to maintain consistent effluent quality.

| Influent Maximum | Influent Minimum | Influent Average | Effluent Average CONTRAFAST -E | Effluent Removal Percentage | |

|---|---|---|---|---|---|

| Arsenic | 7.3646 | 0.1739 | 1.4201 | 0.0459 | 96.8 |