EvenFlo® Retrofit Cuts Effluent Solids

Large Iron Ore Pellet Producer Achieves Water Clarity Goal

Problem

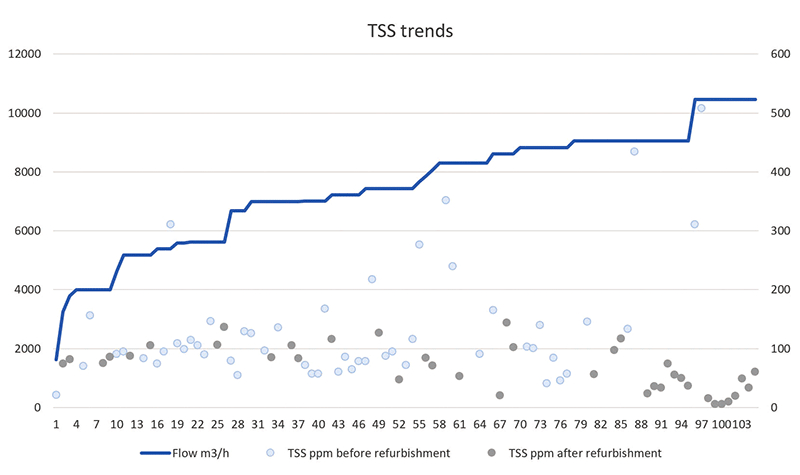

When LKAB, Europe’s largest producer of iron ore pellets, found it necessary to replace two feedwells at its processing plant near Gällivare, Sweden, the company reached out to Alteco System AB, a small engineering company based in Gällivare. LKAB’s small, very old feedwells were significantly affecting the effluent clarity produced by the thickeners in which they had been installed many decades ago. On average, the effluent from these thickeners contained about 190 parts per million (ppm) total suspended solids (TSS), with spikes of 1,000 ppm or more.

The two 40-meter-diameter thickeners were part of the plant’s cold process and were located outside. This system was meant to treat the plant’s process water for reuse; however, the high TSS in the effluent was making reuse difficult. LKAB’s target TSS for reuse was 100 ppm, with an expected flow of 5,000 m3/h for each thickener (total 10,000 m3/h).

Analysis of Alternatives

Upon accepting the project, Vinab (the main contractor for the project) began making inquiries with the assistance of Alteco. Alteco contacted WesTech, a global supplier with process experts throughout the world, about our patented EvenFlo® feedwell and also reached out to, and received quotes from, a few WesTech competitors.

Recommended Solution

Alteco selected the EvenFlo based on its design features and capabilities, and on our relationship with nearby fabrication shops, which enabled us to reduce costs. WesTech subsequently received a purchase order for two 10-meter-diameter EvenFlo feedwells to replace the existing 5-meter-diameter equipment – and for two new CP80 drive units – through Vinab.

The EvenFlo’s advanced two-stage design improves thickener overflow clarity while using lower polymer dosages. The first stage uses an inner channel to convert the tangential feed energy into a concentric radial flow. The second stage, which begins when the flow exits the inner channel via bottom ports, directs the flow radially outward into the main feedwell for optimal solids-flocculant mixing.

The EvenFlo uniquely uses all of the feedwell volume, providing even distribution into the thickener by addressing several issues that commonly occur with traditional feedwell designs, including short circuiting and inefficient flocculation.

Implementation

Vinab began by removing all equipment from the two thickener basins, after which it installed a new center column, bridge, WesTech drive unit and EvenFlo feedwell, and rake arms in each. The two EvenFlo units were fabricated of stainless-steel. Although the retrofitted thickeners achieved (on average) lower TSS than LKAB’s target clarity of 100 ppm, WesTech engineers in Salt Lake City determined that they could further improve the thickeners’ performance. The actual influent flow rate was 7,400 m3/h (3,700 m3/h per thickener), which was lower than the design flow rate of 10,000 m3/h (5,000 m3/h per thickener). With a properly designed EvenFlo, the higher the flow, the greater its performance.

With all of the inner ports open based upon the 5,000 m3/h per unit design flow, the influent did not have time for optimal deaeration. As a result, encapsulated air in the sludge was generating a slight amount of surface foam. By closing a sufficient number of ports in the EvenFlo’s inner circle to account for the lower influent flow rates, the EvenFlo feedwells were able to prolong the influent’s time in the feedwell, allowing proper deaeration, eliminating foam, and improving effluent clarity.

Results

With the optimized EvenFlo feedwells, the plant’s refurbished thickeners have achieved an average TSS level of 70 ppm – approximately a third of the solids level the plant had seen over the life of its thickeners. The units achieve this remarkable clarity with possibilities to also attain much lower chemical dosages, reducing the plant’s operational costs.

LKAB is pleased with the outcome of this project.