High Rate Sludge Removal

COP™ Spiral Blade Clarifier

Treatment History

Medford Regional Water Reclamation Facility (WRF) started treating wastewater in the Medford area in the late 1960s. The facility now serves the entire city of Medford and several surrounding areas. It treats an average of 20 million gallons per day (MGD) of wastewater but can handle the 70 MGD that occasional winters bring.

To keep up with new technologies and the constantly growing needs of the surrounding area’s population, Medford Regional WRF has undergone several upgrades and expansions.

In 1999, as part of a facility upgrade, Medford installed one suction secondary clarifier from WesTech to accommodate increased flows.

| Quantity | Design Flow Rate | Dimensions | Sludge Collection | EDI Configuration |

|---|---|---|---|---|

| 5 | 12 MGD per unit | 90 ft diameter | Spiral blades | Dual gate |

COP Clarifier Update

In 2011, Medford upgraded its facility and again chose WesTech to replace the facility’s clarifiers with COP™ (Clarifier Optimization Package) spiral blade clarifiers. Components such as a flocculating feedwell, spiral rake blades, a sludge withdrawal ring, and an energy dissipating inlet (EDI) make the COP one of WesTech’s most efficient clarifiers. These components work together to optimize the clarification process from influent to effluent.

COP Clarifier

Medford’s new clarifiers have a dual gate EDI, which decreases the horizontal velocity of the feed from the center column into the feedwell. The EDI uses two perpendicular gates to force influent streams into one another to create an impinged flow. This decreases the influent’s kinetic energy and increases particle interaction. Paired with the COP’s large feedwell, the EDI encourages optimal flocculation that promotes settling.

WesTech sizes its sludge withdrawal ring to 20 percent of the basin’s diameter, where the concentration of settled solids on the floor is the greatest. The spiral rake blade design quickly transports the settled solids to the center of the tank, eliminating radial suction systems that lead to plugged orifices or pipes.

WesTech’s sludge withdrawal ring rapidly removes the solids while maintaining a sufficient blanket depth. This decreases dilution and increases the sludge’s concentration. As an added benefit, the sludge ring is fixed in the tank, which eliminates the need to change underwater seals.

Comparison

A common misconception about secondary clarification is that settled solids, particularly in large basins, should be removed from the basin floor using a suction removal system, as opposed to a system that conveys sludge to the center of the tank for removal.

This misconception is based on the assumption that secondary biosolids are too light to be efficiently moved to the center without danger of resuspending them. Hundreds of COP clarifier installations, including the installations at Medford, demonstrate the fallacy of this assumption.

Properly designed spiral rake blades are very effective at conveying settled solids, often achieving lower solids inventories in clarifiers than do suction systems at the same return activated sludge (RAS) flow rate. Plants that have replaced suction clarifiers with WesTech COP clarifiers often report that they are able to reduce RAS flow (and thus power consumption), giving them a higher RAS concentration without increasing the depth of their sludge blanket or impacting clarifier effluent performance.

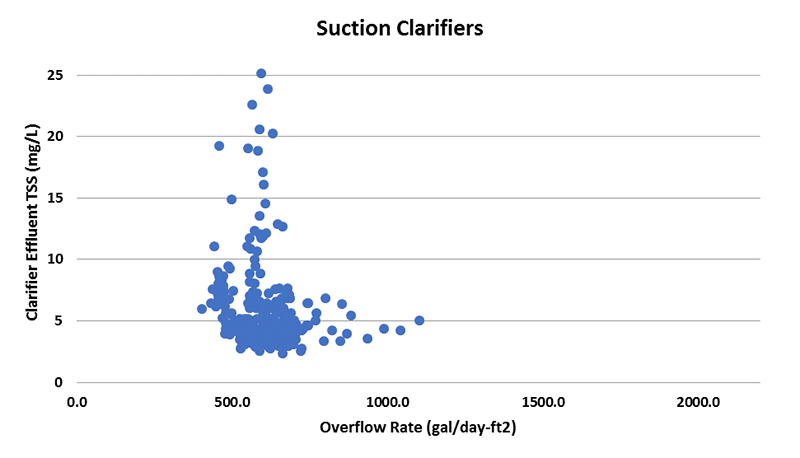

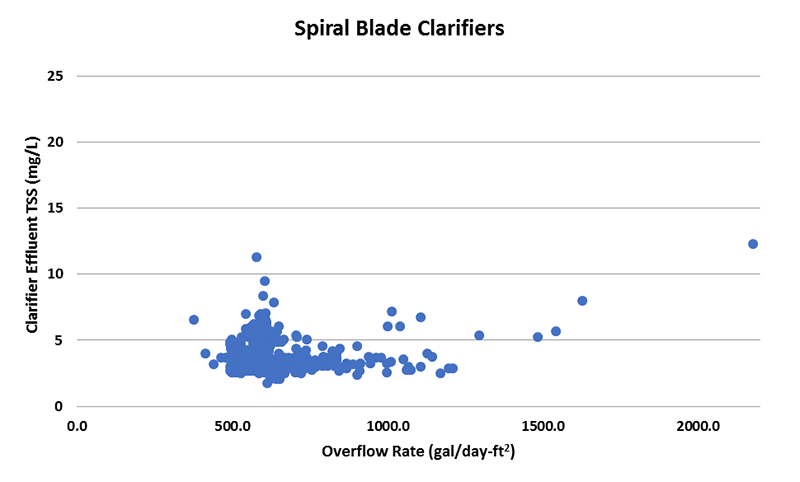

The two graphs show the relationship between clarifier overflow rate and effluent total suspended solids (TSS) for the Medford plant over a year. The first graph displays data from the suction clarifiers that the facility previously operated. The second shows data from the spiral blade clarifiers the facility now operates.

The facility’s flows have increased since updating the clarifiers. The graphs show that even at higher overflow rates, the spiral blade clarifiers produce an extremely low clarifier effluent TSS, releasing >10 mg/L TSS from the plant effluent only twice in the entire year. These clarifiers average only 4.2 mg/L.

In contrast, the suction units averaged 5.6 mg/L, having 26 daily TSS measurements >10 mg/L in a year.

COP spiral blade clarifiers remove sludge at a high rate and concentration while keeping the clarifier effluent TSS well below the facility’s permit allowance of 30 mg/L in winter and 10 mg/L in summer.

On-site Testing

In July of 2018, WesTech performed several tests on Medford’s clarifiers, two of which were to determine the lowest possible effluent TSS achievable for the plant’s biosolids. One tested flocculated suspended solids (FSS), providing gentle mixing to promote an ideal environment for flocculation. The other tested dispersed suspended solids (DSS), providing a calm environment free of currents.

Together, the tests demonstrated that in ideal conditions, the plant’s biosolids could settle to produce effluent with an average TSS of 2.5 mg/L.

The actual TSS of 4.2 mg/L closely approaches this best theoretical performance, showing that the clarifiers are performing phenomenally.

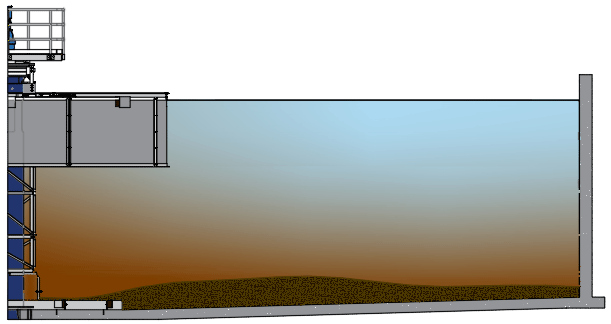

WesTech also ran tests to produce a profile of the sludge blanket on the clarifier floor. The cross-section rendering shown here was produced by taking sludge measurements at different flows and times throughout the day when the rake blade was 90 degrees away from the testing zone on either side. Medford runs its RAS at a high flow rate to keep its sludge blanket around a foot deep. If necessary, the facility could decrease its RAS rate, which would increase the sludge blanket depth and RAS concentration to achieve better dewatering.

As the rendering illustrates, spiral blades push the sludge toward the center of the clarifier, where it is constantly being withdrawn through the sludge ring. The removal process is quick and efficient while keeping the water quiescent enough to not resuspend solids.

WesTech’s COP spiral blade clarifiers have optimized the clarification process. Medford’s operators and management are pleased with the clarifiers’ performance and ease of maintenance. Dale Crum, Medford’s process control supervisor, says “[The facility runs] them 24 hours a day, 365 days a year and they actually work very well. [They] run all five in winter and drop them down as needed in the summer.” Medford has appreciated the COP clarifiers’ longevity, reliability, and the fact that they never clog like suction clarifiers do.