City of Napa Meets ZLD Requirement

Fill and Decant Backwash Clarifiers

Facility Upgrades

The Edward I. Barwick Jamieson Canyon Water Treatment Plant located in the City of Napa, California, treats water for domestic and winery use. With growing populations and an aging plant, Napa needed to upgrade its treatment facility. The current system employs coagulation, flocculation, clarification, filtration, lagoons, and drying beds.

Napa is classified as a zero liquid discharge site. Due to this classification, no spent water can be released from the site, requiring on-site thickening and solar evaporation. To reduce the amount of water evaporating, increase capacity, and “go green,” the city decided to treat its backwash water. In 2009, Napa upgraded its water treatment plant and increased capacity from 14 MGD to 21 MGD.

Spent water from backwashes and clarifiers is typically between 16-21 times more concentrated with giardia and cryptosporidium than raw water. To ensure removal of these harmful contaminants, California State Law (under the Filter Backwash Recycling Rule) regulates spent filter backwash water quality.

Backwash water used in filtration and clarifier underflow is treated to <2 NTU and is pumped to the flocculators at the front of the plant.

| Treated wastewater return flow | Up to 10% total plant flow |

|---|---|

| Turbidity | <2 NTU |

When simple treatment technologies do not reduce turbidity below 2 NTU, spent water may be treated to match the raw influent quality. To prevent overloading the plant, up to 10% of total plant flow can be returned for recycling. With the current water demand, Napa sends 8 percent of its treated wash water to the front of their plant for reuse.

While many spent filter backwash water treatment technologies are available, the City of Napa decided to treat through thickening and clarification due to cost and required maintenance. To reduce the footprint, Napa explored the option of having a single basin for both thickening and clarification.

WesTech performed a series of laboratory tests on a backwash water sample in order to optimize the size of the basin, allowing for thickening and clarification to occur in the same basin.

Equipment Selection

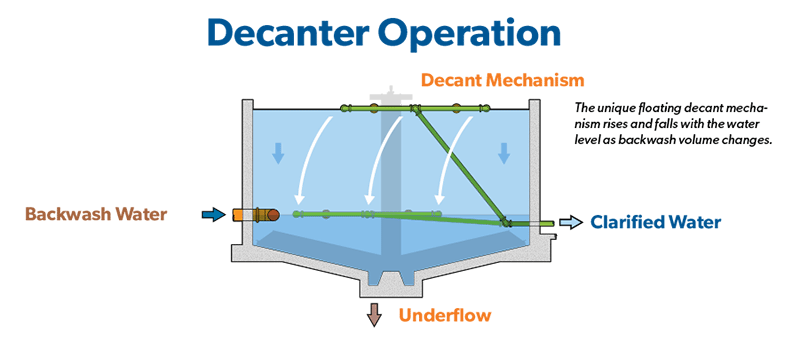

Following the study, WesTech was contracted to supply two 60 ft diameter fill and decant backwash clarifiers. The water depth in the clarifiers ranges from 8 ft to 29.5 ft depending on the backwash flow. The unique floating decant mechanism rises and falls with the water level as backwash volume changes. As backwash flow is not constant, but rather short surges of high flow, equalization is required prior to treatment.

| Quantity | 2 |

|---|---|

| Size | 60 ft diameter |

| Solids loading rate | 40 lbs/day/ft2 |

| Solids | Peak: 10,000 lbs/day Average: 6,000 lbs/day |

| Total working volume | 1.7 MGD |

WesTech’s Fill and Decant Clarifiers are an effective way to combine equalization and treatment of spent filter backwash in the same basin. The clarifier basin is designed with enough capacity to accommodate the backwash surge volume, thus eliminating the need for separate equalization. After the backwash water fills the basin, the solids are allowed to settle and then the clarified supernatant is evenly drawn off by the floating decanter.

| Full-Scale Operation | Bench-Scale Study | |

|---|---|---|

| Influent turbidity | 65-90 NTU | 79.3 NTU |

| Supernatant polymer dose | 0.0 mg/L | 0.4 mg/L |

| Supernatant turbidity | <2 NTU | 0.7 NTU |

| Underflow concentration % solids | 3% | 1.9% |

Intelligent Solutions

Because of the effectiveness of the fill and decant clarifier, California State requirements were met without the addition of a polymer into the clarifier. WesTech’s research has shown that with the addition of a polymer, turbidity can be decreased to <0.7 NTU. The chief operator, Paul Prewitt, said that they are “very happy with equipment and process” WesTech provided and water quality exceeds their expectations.

With the zero liquid discharge requirement, Napa treats the majority of its water with the fill and decant Clarifier to thicken solids and reclaim water. After the clarifier, water is sent to lagoons and the sludge is thickened in drying beds. With the new system, up to 98 percent of all water going through the plant is reclaimed and drying times have been reduced.

With the new WesTech equipment, the city’s water reuse goals have been met and operations and maintenance have been simplified. “Operators that have been there for a number of years are very happy with this simplified system” said Prewitt. Things are “running smoothly and require only minor attention.”