Biological Filtration

ESSD Washtroughs, MULTIWASH® Backwash and MULTICRETE™ II Underdrain

Problem

The City of Albuquerque concluded in the 1990s that its aquifer drawdown exceeded its recharge. The city needed to look into a new water source to provide 80-92 MGD of water to its 600,000 population – representing 50 percent of the water demand in the state of New Mexico. In addition, the U.S. Environmental Protection Agency (EPA) was preparing to lower the arsenic maximum contaminant level (MCL) from 50 ppb to less than 10 ppb, making Albuquerque’s groundwater one of the largest water sources impacted by the regulation. The solution was to tap into Rio Grande surface water rights to meet 70-80 percent of the water demand. To meet the rest of the demand, a blend of groundwater would keep the arsenic concentrations below the MCL. This became known as the San Juan-Chama Drinking Water Project by the Albuquerque Bernalillo County Water Utility Authority (ABCWUA). CH2M was selected as the consulting engineering firm. The new water treatment plant finished construction in 2008.

Switching over from a groundwater to surface water source presented several challenges. Taste and odor compounds and disinfection byproducts were among the challenges.

| Parameter | Minimum | Average | Maximum |

|---|---|---|---|

| TOC | 2 mg/L | 3.9 mg/L | 6 mg/L |

| Alkalinity | 96 mg-CaCO3/L | 121 mg-CaCO3/L | 175 mg-CaCO3/L |

| pH | 7.8 | 8.3 | 8.9 |

| Temperature | 41°F | 62°F | 83°F |

| Fe | 0.7 mg/L | 2.4 mg/L | 11.2 mg/L |

| Mn | Non-detect | Non-detect | Non-detect |

Solution

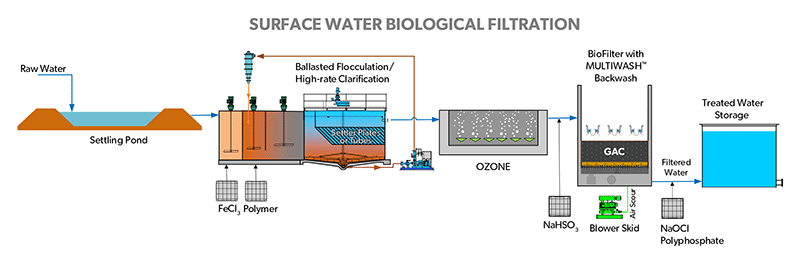

The engineer selected a multiple-barrier treatment process that had success at other plants such as El Paso, Texas; Woodland & Davis, California; Fresno, California; and Tampa, Florida. The process provides redundancy to remove organics by first using enhanced coagulation with a high-rate clarification process followed by ozone and biofiltration (O3/BAF). WesTech/General Filter supplied the biological filter underdrains and washtroughs.

| Parameter | In | Out |

|---|---|---|

| NTU | 4-5 | 0.03-0.04 |

| TOC | 1-2 | 0.8-1.4 |

The plant has 12 26 feet x 40 feet biological filters containing 60 inches of granular activated carbon (GAC) and 12 inches of sand. The filters receive ozonated water. The operators have the ability to feed sodium hypochlorite or hydrogen peroxide to control the biological growth, if necessary.

The filter components include General Filter ESSD low-profile media retaining washtroughs with baffles to separate the air from the water during MULTIWASH® air/water backwash to prevent GAC media loss. The MULTICRETE™ II underdrain system has an accessible underdrain plenum and plastic media retaining nozzles to prevent corrosion from the GAC and to maintain a low filter profile by eliminating the need for gravel support layers.

Implementation

The sorptive capacity of the GAC exhausted quickly within six months after startup. Fortunately, the water utility relies on biological treatment rather than sorption to remove organics.

Changing out all the GAC media in the ABCWUA plant every six months would have cost about $5 million wholesale, compared to $0.5 million to top off approximately 6-9 inches every four years. Without the biological process, this could be a cost-prohibitive operating expense for utilities considering this process.

The ABCWUA plant manager and chief engineer reported that the filters work well without any problems and are maintenance free. The water utility now has time to optimize the backwash process to minimize waste volume and media loss.

Results

Turbidity: The water utility is preparing to become a subscriber of the AWWA Partnership for Safe Water since the filter effluent is less than 0.1 NTU over 99 percent of the time. The filters currently reduce 4-5 NTU turbidity down to 0.03-0.04 NTU.

The filters are designed to operate up to 6 gpm/ft2.

Organics: The surface water plant reduces raw total organic carbon (TOC) by approximately 60 percent. One-third of that reduction occurs in the filters. The plant relies on biological, not sorptive, processes in the filters to reduce organics. In fact, after the filters were topped off with new GAC in 2012, there was a brief decrease in the TOC removal efficiency while the filters re-established their biomass in the top layer.

Backwash: The filters typically backwash every 60-100 hours of operation. The 100 hours setpoint is a state regulated maximum filtration time between backwashes. The filters usually backwash based on filter run length or differential pressure (8 feet of water setpoint). The first step is a low-rate air/water backwash with 3 cfm/ft2 air and 5 gpm/ft2 water. The second step is an air purge/re-stratification high-rate backwash with 15-17 gpm/ft2 water. The water rates are adjusted with varying water temperatures. A filter to waste step is included at the end of the backwash process.

| Step | Rate | Duration |

|---|---|---|

| Combined air/water | 3 cfm/ft2 air 5 gpm/ft2 water |

5 minutes |

| Re-stratification | 15 gpm/ft2 water | 10 minutes |

| Filter-to-waste | 3-6 gpm/ft2 water | 15 minutes |

Switching over from a relatively pristine groundwater source to a surface water source could have had some negative effects to its customers like taste and odor. Fortunately, the ozone plus biofiltration process has helped remove organics and contributed to good tasting finished water for over half a million customers in Albuquerque, New Mexico.

| Chemical | Purpose | Active Dose |

|---|---|---|

| Ferric chloride | Coagulant | 15-50 mg/L |

| Polymer | Settling aid | 0.2-1.0 mg/L |

| Lime | Raise pH | 20-40 mg/L |

| Ozone | Oxidant/disinfection | 1.0-2.0 mg/L |

| Sodium bisulfite | Quench O3 | 0.75-1.0 mg/L |

| Sodium hypochlorite | Disinfection | 1.5-2.5 mg/L |

| Polyphosphate | Corrosion inhibitor | 0.5-1.0 mg/L |