Removal of Iron and Manganese

Horizontal Pressure Filters with ANTHRA/SAND™ Media

A Need for Cost Savings

The Pottawatomie County Water Treatment Plant provides drinking water for Kansas Rural Water District No. 4. Two wells supply the majority of the county’s water.

To meet the secondary maximum contaminant level (MCL) for iron and manganese, Pottawatomie used cartridge filters followed by reverse osmosis (RO) for softening. Because of influent water quality, the cartridge filters needed to be replaced every other day, resulting in large operating costs and demanding significant operator attention.

The treatment plant was falling short of the secondary standards and set a goal of 0.05 mg/L for both iron and manganese.

| Secondary MCL | Treatment Objective | Well 1 Raw Water | Well 2 Raw Water | |

|---|---|---|---|---|

| Iron | 0.3 mg/L | 0.05 mg/L | 0.32 mg/L | 0.62 mg/L |

| Manganese | 0.05 mg/L | 0.05 mg/L | 0.04 mg/L | 0.05 mg/L |

Equipment Selection

In order to meet this standard, the engineer decided that a granular media filtration system would more efficiently serve the residents of Pottawatomie County and reduce maintenance hassles. Compared to cartridge filters, granular media filters resulted in better water quality, lower operating costs, and reduced fouling of the RO membrane.

In 2011, Pottawatomie installed one WesTech Horizontal Pressure Filter with manganese ANTHRA/SAND™ media to remove iron and manganese. ANTHRA/SAND media catalytically removes soluble manganese and particulate iron from water in the exact same manner as manganese greensand.

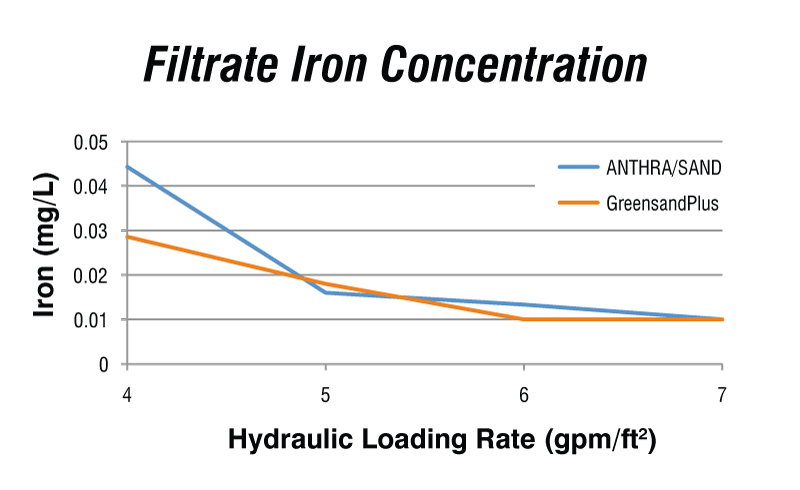

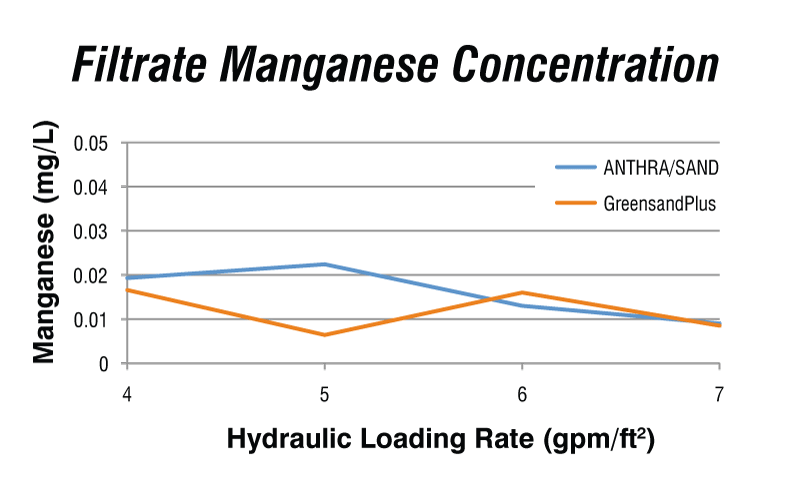

At startup, WesTech conditions its iron and manganese removal media with the ANTHRA/SAND process after it has been placed in the filter. This conditioning consists of soaking the media for 24 hours in a solution of potassium permanganate and manganese sulfate. The media is then continuously fed with an oxidant to provide permanent regeneration. In a pilot study completed at the Pottawatomie Water Treatment Facility, ANTHRA/SAND was proven to be as effective and efficient as the leading manufactured manganese greensand, GreensandPlus. This efficiency can be seen in comparable effluent qualities between ANTHRA/SAND and GreensandPlus, when supplied with similar influent water qualities.

| ANTHRA/SAND | GreensandPlus | |

|---|---|---|

| Hydraulic loading rate | 6 gpm | 6 gpm |

| Backwash | 8 gpm 9 min |

4 gpm 17 min |

| Total backwash volume | 72 gallons | 68 gallons |

| Media size | 0.45-0.55 mm | 0.3-0.35 mm |

| Iron influent | 0.620 mg/L | 0.620 mg/L |

| Iron effluent | 0.080 mg/L | 0.092 mg/L |

| Manganese influent | 0.0534 mg/L | 0.0534 mg/L |

| Manganese effluent | 0.006 mg/L | 0.010 mg/L |

Customer Satisfaction

Pressure filters with ANTHRA/SAND produce high-quality water at a fraction of the media cost. ANTHRA/SAND media is conditioned on site, which means costs solely include granular media and chemical treatment. ANTHRA/SAND has many other advantages over GreensandPlus, including: media sizes can be matched to water quality, media is easily recoated in place if needed, and materials are readily available.

Because of the ability to treat various grain sizes, WesTech is able to customize the media size to meet multiple hydraulic loading and backwash rates. With this versatility, media is less likely to wash out or migrate into supporting gravel layers.

| ANTHRA/SAND | GreensandPlus | Naturally Occurring Greensand | |

|---|---|---|---|

| Price | $10/ft3 | $66/ft3 | $85/ft3 |

| Effective size | Variable | 0.3-0.35 mm | 0.3-0.35 mm |

| Availability | Non-proprietary | Proprietary | Proprietary |

| Expected media life | Restorable coating | Restorable coating | 4-8 years |

By replacing inefficient cartridge filters with a horizontal pressure filter, Pottawatomie County saved money and has reduced operator hassle. To increase money savings even further, ANTHRA/SAND filter media was used. Capital costs of this media are initially lower. Additional savings are also seen as media requires replacement.

ANTHRA/SAND has been proven to produce high quality water and provide significant savings over the life of the plant.