Arsenic Removal to Meet EPA Standards

Meeting EPA Regulations

Victor Valley Water District began planning for arsenic removal in early 2001 to be in compliance with the anticipated requirement to increase arsenic removal. In the 2006 EPA regulation change, acceptable arsenic levels were reduced from 50 μg/L to 10 μg/L.

Victor Valley receives its water from 22 active production wells. These wells produce 5.5 billion gallons annually and service 65,000 customers in the San Bernadino Valley. Low to moderate (2 to 21 μg/L) levels of naturally occurring arsenic were found during the testing of the wells. Between 2002 and 2004, nearly half of the wells tested above the 10 μg/L limit.

Victor Valley Water District, with Carollo Engineers, conducted a series of pilot plant studies to compare arsenic removal technologies. A packaged ion exchange system was evaluated against a coagulation/filtration (C/F) process under several different scenarios. After reviewing the pilot plant results and comparing costs, Victor Valley selected the C/F system.

| Cost (Low to High) | Advantages | Disadvantages |

|---|---|---|

| Coagulation/filtration |

|

|

| Lime softening |

|

|

| Adsorptive media |

|

|

| Ion exchange |

|

|

| Membrane filtration |

|

|

| Adapted from Carollo Engineers | ||

Equipment Selection

WesTech was selected to provide a total of 11 vertical pressure filters and supporting instrumentation for the project. 4 pressure filters were placed at the Balsam plant and 7 at the El Evado plant. All 11 filters together produce 15 MGD.

| Dimensions | 12 ft diameter |

|---|---|

| Area per filter | 113 ft2 |

| Filtration rate | Nominal: 6.4 gpm/ft2 (724 gpm) Maximum: 7.5 gpm/ft2 (848 gpm) |

| Backwash flow rate | 20 gpm/ft2 |

While natural arsenic levels were just above the EPA’s limit, the amount of water to treat was sizable. Due to the high flow rate associated with the well sites, significant quantities of large filtration area vessels were required for adequate arsenic removal.

| Media | Depth | Effective Size |

|---|---|---|

| Anthracite coal | 30 in | 1.1 mm |

| Sand | 18 in | 0.55 mm |

WesTech has extensive experience in designing and constructing pressure filters. The large quantity of vessels were customized to match the water quality and remove the desired amount of arsenic.

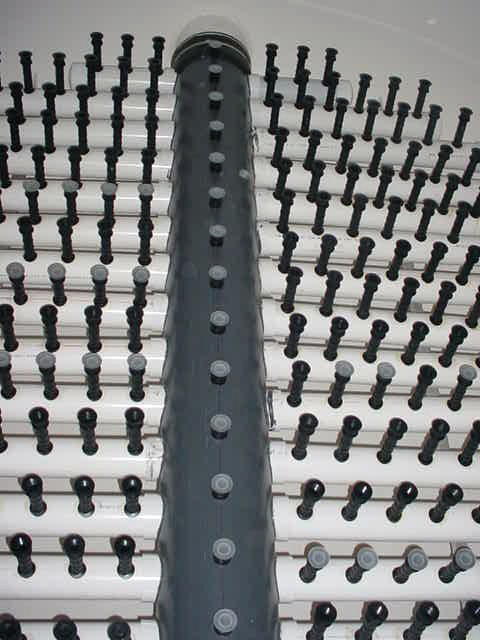

Customized filters provided Victor Valley with the level of performance needed to comply with the EPA requirements. The unique header and lateral underdrain design developed by WesTech, in collaboration with Carollo, ensured uniform distribution of flow in the vessels.

| Before Treatment | After Treatment | |

|---|---|---|

| El Evado | 10.9 μg/L | 8 μg/L |

| Balsam | 12 μg/L | 8 μg/L |

Optimizing the media type and depth, WesTech improved filter run times and provided the most efficient pressure filter for arsenic removal.

Customer Satisfaction

The WesTech Vertical Pressure Filters effectively removed arsenic to meet the EPA standard. Individual, parallel operating vessels satisfy redundancy requirements and offer a design that is easily expanded to meet future needs.

By employing WesTech’s vertical pressure filters, Victor Valley is now in compliance with EPA regulations and consistently produces high quality water to the San Bernadino Valley.