SuperSettler™ Provides Consistent Performance Under Varying Conditions

Cooling Tower Blowdown Treatment Application

Problem

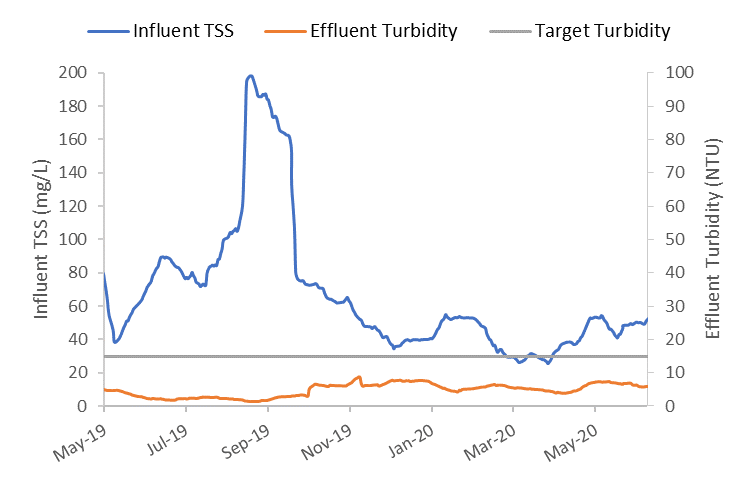

PacifiCorp’s Naughton Power Plant needed clarifier technology to treat approximately 2,300 gpm – or 522 m3/h – of cooling-tower blowdown from three cooling towers at the plant. The blowdown water from the plant’s system contained varying levels of total suspended solids (TSS) that ranged from approximately 150 mg/L to 250 mg/L. PacifiCorp needed a treatment system that would allow it to meet its permit limit of 30 mg/L (monthly average), regardless of the influent TSS levels.

Analysis of Alternatives

McMillen Jacobs worked with WesTech early on to assess the viability of different clarification technologies while pursuing this design build project. Some feedback was provided through existing plant operations and WesTech carried out extensive testing in its on-site laboratory. The plant’s variable flowrates, limited available footprint, and desire to keep equipment indoors, led to the determination that inclined plate clarification technology was best for the project.

Recommended Solution

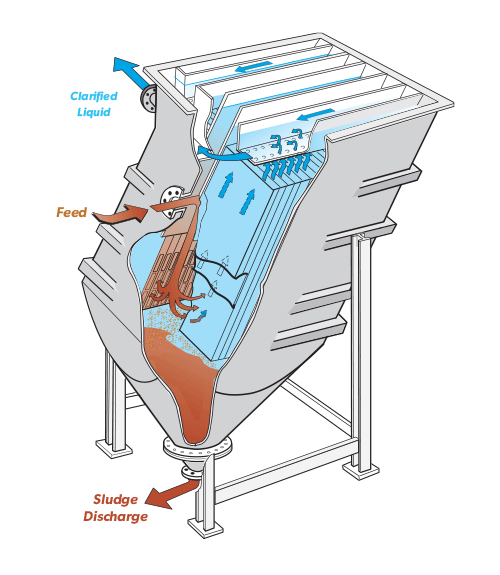

WesTech proposed two SuperSettler™ inclined plate clarifiers as a potential solution to treat the flow levels and TSS content of the feed water at the Naughton plant. The SuperSettler system is extremely adaptable, allowing the plant to adjust chemical dosages to meet daily raw water characteristics and flows. It is designed with inclined plates to provide highly efficient settling in a small footprint. By stacking the plates closely together at an angle, the combined projected settling area constitutes one tenth of the footprint that conventional settling basins require. WesTech also recommended a flocculation tank and chemical dosing to improve clarification.

| PACI Dose | Recirculated TSS | Average Effluent Turbidity |

|---|---|---|

| 4 ppm | ~900 mg/L | <5 NTU |

Implementation

Cooling tower blowdown water has significantly higher temperatures than water from typical sources. The heat reduces dynamic viscosity, which leads to faster settling rates and the potential for higher applied hydraulic loading rates.

However, it can also severely limit the types of polymer that plants can use for flocculation. On this project, the design hydraulic loading rates were almost twice those of typical design values. Additionally, cooling tower operation often requires the use of dispersants, antiscalants, and biocides, which can significantly hinder proper flocculation. As a result, treating cooling tower blowdown requires increased chemical dosing and flocculation-tank detention time.

WesTech conducted several rounds of jar testing, both remotely and on-site, to properly select the polymer and determine effective dosing rates. Remote testing was conducted prior to final equipment design, and on-site testing was conducted during startup to optimize chemical dosing and operating set points and pretreatment. WesTech incorporated solids recirculation for optimized performance to maintain a target solids concentration in the flocculation tank. Solids recirculation and additional detention time in the flocculation tank help counteract surges in feed TSS concentration.

For this project, coagulant is first added in an in-line rapid mixing tee, followed by polymer addition in the flocculation tank. Next, the chemically-treated flow passes to the SuperSettlers to allow the now-flocculated particles to settle. Clarified water exits the top of the plates into collection launders, while settled solids collect on each plate and settle down into the lower collection hopper for eventual sludge discharge.

Results

Because of the flexibility of the new water treatment equipment, the Naughton power plant can switch from running all three cooling towers to running just one or two towers – without experiencing treatment issues. The treatment system periodically requires blowdown, but with the optimized chemistry and solids recirculation inside the clarifiers, sludge wasting can be as infrequent as only two to three times a month for 10 minutes each time.

Despite large fluctuations in influent conditions, the SuperSettlers consistently produce an effluent with solids content well below the discharge standards that the Naughton power plant is required to meet. To simplify live monitoring, the plant has established an internal turbidity goal of <15 NTU in the SuperSettler effluent, which ensures it will meet the monthly average TSS target of <30 mg/L. With solids recirculation and optimized chemical addition, the plant can avoid overtreating the water, reducing sludge output. Chemical-feed optimization has such a significant impact on chemical consumption that the plant is currently using less than 10 percent of its original operating budget. WesTech engineers and chemists worked diligently to overcome the different obstacles posed by the feed conditions and create a reliable and cost-efficient system for water treatment at PacifiCorp’s Naughton power plant.

After installation and startup was completed, WesTech’s lab technicians provided an additional benefit by helping train the on-site chemists to conduct their own ongoing jar testing. This allows the site to continue fine tuning the dosages and to identify potential polymer alternatives that could be more effective.