Deep Bed™ Thickener in High Rainfall Area

Design Incorporates Benefits of Surface Stacking for Effective Water Management

Problem and Analysis of Alternatives

A gold mine located in the steep mountain area of sub-tropical China retrofitted one of its slurry ponds to convert to a surface stack technology. The tailings storage facility (TSF) is located in a canyon near the mine. The narrow canyon is dammed at the mouth, providing an area of about 6.3 hectares.

The TSF feed is the discharge stream from a process water treatment plant using Na2S and CaO to remove dissolved salts. The metal precipitate has a fine particle size distribution (PSD), and is difficult to flocculate and capture. The water must be recycled as it does not meet discharge criteria.

The monsoon-influenced climate gives heaviest rain in the spring to early summer (greater than 200 mm per month) with over 1.7 meters of rainfall a year. The operation of a slurry pond requires the recovery of water, including rainwater. The recovered pond water does not meet discharge requirements and must be recycled. The rainwater collected from the slurry pond TSF creates a water balance problem. An optimization study focused on a solution that would incorporate the benefits of surface stacking technology to avoid the water imbalance and minimize process water going into the pond.

The goal of the design was to:

- Provide a safe and effective disposal of the tailings

- Improve the overall physical characteristics of the deposits

- Maximize water recovery at the thickener

- Keep rainwater separate from process stream water

Recommended Solutions

The mine site determined that implementing surface stacking of the underflow from a paste-type thickener, paste and thickened tailings (P&TT), would provide the following benefits:

- Dewatering the process stream in a paste-type thickener recovers significantly more water at the plant. The water in the underflow evaporates in the TSF and does not pool like the slurry method. Water balance control is simplified, recovering the water at the plant.

- Without requiring water to be collected from the pond, the rainwater does not add to the water balance.

- The final tailings density is greater with P&TT, increasing the TSF capacity.

Issues With Drying in a Sub-Tropical Climate

Though surface stack techniques have been successful in a variety of climates around the world, there is still concern about whether the techniques are effective in heavy rainfall areas.

The mine conducted a pilot-scale deposition and drying investigation after the installation of the paste thickener to quantify the benefits and refine the site management plan. A 10 m by 10 m test site was prepared next to the TSF and was filled to about 500 mm deep with P&TT. Due to the very fine PSD, this non-Newtonian underflow has the design yield stress at about 28-29 weight percent (wt%) solids (see photo 1).

The rapid consolidation and drying allowed foot traffic by the fourth day, despite 15 mm of rain that day (photo 2). Drying continued quickly, with large cracks developing by day seven (see photo 3). Day 10 shows the deposit after two rain events, dried to significant cracking. At this point about half of the water has evaporated (see photo 4).

This study showed that the rapid drying of surface stacking and the low yield stress P&TT is a safe and stable method of tailings disposal in a sub-tropical climate.

Implementation

The installed 15 m diameter WesTech Deep Bed™ Paste Thickener on a hill near the TSF (photo 5) effectively dewaters to a non-Newtonian density, P&TT, and recovers clear water for recycling. The low-yield stress P&TT is pumped a short distance to the TSF by centrifugal pumps.

The initial spigots were placed along one side of the TSF, forcing the pond water from the previous pond slurry to collect near the dam where this water was recovered. The TSF had relatively no standing water after about three months of operation. Photo 6 shows the TSF during the first monsoon season.

Once the water was collected, the spigot placement was shifted to other locations around the TSF, eventually settling on the arrangement of spigots located along the dam. Rotating active spigot locations allows drying between layers for stability (see photo 7). The gentle 1-3 percent deposition slope drains rain from the surface at mild velocities to minimize erosion of the solids and keep the solids exposed for continued air drying. The site management plan did not recover rain runoff collected in the TSF footprint but left it in the TSF to absorb and ultimately evaporate.

Results: TSF Life and Closure

The small footprint of the TSF resulted in a relatively fast dam rise rate. The slurry pond was near capacity when the WesTech Deep Bed paste thickener was installed. A dam raise was needed at the end of year one after the surface stack was begun.

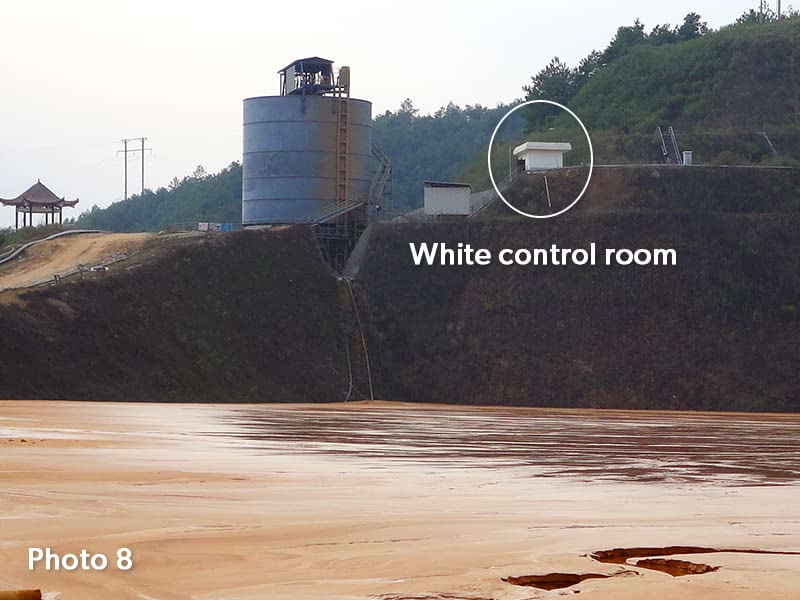

Over five years of operation, the dam elevation increased over 20 meters. Comparing photos 8 and 9, the white control room building can be used as an elevation reference. At this point, the TSF filled to capacity, encroaching on roadways and other facilities.

Rapid drying of the Deep Bed thickener underflow throughout the years allowed the plant to have quick access to the TSF once it was filled. The capping process quickly followed closure of the site (see photo 10).