SuperSand™ Filters Produce Effluent <1 NTU

Environmental Challenges

For the past 85 years, Boca Raton maintained contaminant levels well below federal wastewater treatment discharge standards, protecting aquifer recharge sites and the Florida Everglades from contamination. With growing populations, demand exceeded the capacity of the treatment plant and threatened its ability to maintain a high level of treatment. To continue the high level of service, the city decided to expand its treatment plant.

Working with Eckler Engineering, Boca Raton began plans for the wastewater treatment plant expansion in 2009. To protect the environment and anticipate future regulations, the treatment plant was designed to always discharge <1 NTU, where the statewide standard required <2.2 NTU.

In the past, Boca Raton used aeration and clarification followed by 24 continuous backwash sand filters for tertiary treatment. Because of the ease of operation and excellent performance of these filters, they were the basis of design for the expansion to run in parallel with the existing sand filters.

Equipment Selection

Due to WesTech’s responsiveness and customer service, it was selected to provide 32 SuperSand™ continuous backwash sand filter modules.

| Quantity | 32 modules |

|---|---|

| Configuration | 8 concrete basins 4 modules per basin |

| Maximum daily flow | 6,950 gpm |

| Design filtration rate | 4.4 gpm/ft2 |

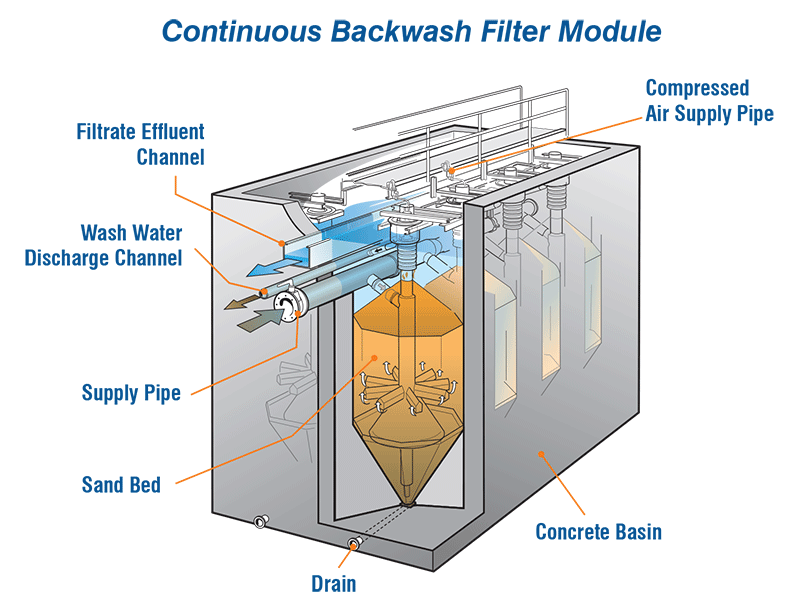

Continuous backwash filters are upflow moving-bed filters where secondary clarifier effluent enters near the bottom and solids are filtered as the water flows up through the media bed. As the filtrate reaches the top of the filter, it passes over the effluent weir and leaves the tank.

A portion of the filtrate is diverted through the sand washer and used for cleaning and conveying the waste solids. WesTech’s continuous backwash filters can be installed in a multi-module, common sand bed configuration or as freestanding units. Due to the high flow at Boca Raton, the common sand bed configuration was the most efficient design.

The filters provide uninterrupted flow due to the continuous backwash. This eliminates the large backwash holding tanks and backwash pumps required with other filtration methods. WesTech designed the continuous backwash filter system with a minimal waste stream for disposal or further treatment. Continuous backwash filters can be housed within a small footprint with no moving parts.

This system provides simple operation while reducing energy and maintenance costs. Through the plant, the system achieves on average 96 percent and 98 percent of TSS and CBOD5 removal, respectively.

| Maximum Level | Influent | Effluent | |

|---|---|---|---|

| Turbidity | <2 NTU | Range: 1.25-5.31 NTU Average: 2.96 NTU |

Range: 0.25-0.49 NTU Average: 0.38 NTU |

| TSS | 30 mg/L | 185 mg/L | 6 mg/L 96% removal |

| CBOD5 | 25 mg/L | 190 mg/L | 3 mg/L 98% removal |

Exceeding Expectations

Due to the effectiveness of the continuous backwash filter units, Boca Raton on average achieves turbidity around 0.4 NTU without the addition of a polymer. Once a month, 5 mg/L of polymer is dosed and the plant achieves turbidity as low as 0.3 mg/L.

During the full scale performance test, the filter influent was spiked to artificially increase the influent to 10 NTU. WesTech’s continuous backwash filters consistently produced turbidity levels below 1 NTU.

With the new WesTech SuperSand continuous backwash filters, Boca Raton was able to increase the amount of reuse water produced and treat water to well below the discharge limits. Operator Eddie Catalano said that they are “very happy with the performance and service” WesTech provided.

Over the past year, WesTech has made quarterly visits to optimize the filters and ensure the highest level of performance.

Through the use of WesTech’s continuous backwash filters, Boca Raton continues to meet and exceed its goal of protecting the aquifers and the Florida Everglades.