The Green River Turns Clear

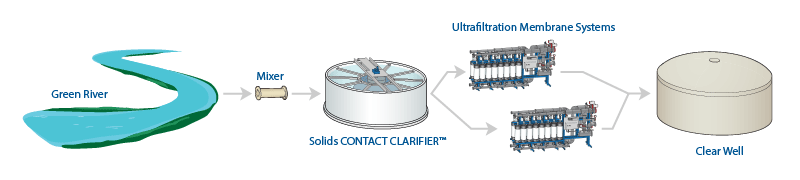

Ultrafiltration Membrane System and Solids CONTACT CLARIFIER™

New Water Source Challenge

The Town of LaBarge, Wyoming, is home to nearly 500 residents. In the past, drinking water was drawn from a groundwater source and required only chlorination. When the infiltration gallery collapsed, the groundwater supply diminished and another source was needed.

The Green River was used to supplement the groundwater but required further treatment. As an interim solution to meet EPA regulations, LaBarge rented a small ultrafiltration membrane skid from WesTech. This direct filtration system provided interim treatment while the new treatment plant was designed and built.

During spring runoff, turbidity levels in the Green River reached over 1100 NTU. As there was no pretreatment, the membranes would blind off quickly, requiring frequent backwash. The town needed a more permanent and comprehensive drinking water system.

Equipment Selection

The town council, in conjunction with the engineer, selected a permanent membrane filtration system with clarifier pretreatment. WesTech was chosen to provide all of the major process equipment for the new facility including one Solids CONTACT CLARIFER™ and two ultrafiltration membrane filters.

For pretreatment, a Solids CONTACT CLARIFIER was the best fit to treat raw water from the Green River. The WesTech Solids CONTACT CLARIFIER is an enhanced flocculation device with internal solids recirculation, gentle flocculation, and gravity sedimentation in a single unit. Compared to a conventional clarifier, higher volume internal solids recirculation and lower floc shear are provided by the Solids CONTACT CLARIFIER, while using less horsepower.

| Solids CONTACT CLARIFIER | |

|---|---|

| Size | 30 ft diameter |

| Flow rate | Design: 425 gpm Hydraulic peak: 530 gpm |

| Hydraulic loading rate | 0.72 gpm/ft2 |

| Recirculation rate | 2,550 gpm |

| Detention time | Total: 175 min Flocculation: 30 min |

| Motor HP | Rake Arm Drive: 0.5 Impeller Drive: 1 |

| Coagulant dose | Range: 40-50 ppm |

By effectively reducing iron, manganese, turbidity, and TOC, Solids CONTACT CLARIFERS have demonstrated their ability to provide excellent pretreatment to membrane filters. Improved clarification also reduces the cleaning frequency and chemicals needed to maintain a membrane filtration system.

Operating with internal solids recirculation and a sludge blanket, the Solids CONTACT CLARIFER allows for enmeshment of uncoagulated material in the event of high turbidity spikes or a coagulation system shutdown. The sludge blanket provides an additional buffer in the event the coagulant dose requires adjustment.

| Treatment Plant Turbidity | |

|---|---|

| Raw water | Range: 10-1,180 NTU Average: 17 NTU |

| Clarifier effluent | Range: 0.07-3.2 NTU |

| Ultrafiltration membrane effluent | Range: 0.02-0.06 NTU |

During spring runoff in 2011, the LaBarge Treatment Plant operated for approximately one week without the addition of alum while waiting for a chemical delivery.

After carefully monitoring the system, the plant was pleasantly surprised when the clarifier continued to produce water with turbidity levels of <5 NTU. Because of the effectiveness of the Solids CONTACT CLARIFIER, the membranes were not fouled and LaBarge was able to continue providing high quality water to the town.

The WesTech Ultrafiltration Membrane System has a pore size of 0.01 µm, providing the highest level of pathogen and particulate matter removal available for low-pressure membrane filters. The system also consistently produces the highest possible quality filtrate, with greater than 4 log removal of cryptosporidium and giardia.

| Ultrafiltration System | |

|---|---|

| Quantity | 2 trains 16 modules per train |

| Ultimate capacity | 32 modules |

| Modules supplied | 26 modules |

| Permeate production | 600 gpm |

| Build-out capacity | 6 modules 140 gpm |

| Design flux | 30 GFD |

| Recovery | 96% |

The engineer selected a 32-module system for the Town of LaBarge. With the current demand, 26 modules were purchased and are in operation. To allow for future growth, LaBarge can add the remaining 6 modules and increase the capacity by 140 gpm.

Through the clarification and membrane ultrafiltration process, water has consistently met or exceeded EPA standards since the beginning of operation in the fall of 2010.

Water quality has remained stable even during high flows and/or without coagulant. Town officials were impressed with the simplicity and low maintenance requirements of the membrane filtration system.

With the fully automated system, adjustments to plant operations could be made entirely from the control room. Simplicity was essential since the operators at LaBarge have many other responsibilities at the plant. In addition to the simplicity of the treatment equipment, the operators were also pleased with the high quality of water produced.

With unmatched customer service, WesTech’s Solids CONTACT CLARIFIER and Ultrafiltration Membrane System supplied a long-term, high-quality treatment solution to meet the drinking water needs for the Town of LaBarge.