Optimizing Water Recovery and Improving Tailings Storage Safety

Titan™ Traction Thickeners and Deep Bed™ Paste Thickeners

Master Plan

Khumani Iron Ore Mine is situated in the Northern Cape Province of South Africa. The area supports a number of large mining ventures where allocations of raw water are limited and carefully managed. This led to challenges when designing the mine.

Khumani paste disposal facility began production in July 2008. Initial production rate was 8.4 million tons/annum (t/a), increasing to 10 million t/a, and reached 16.8 million t/a by 2012.

The design team needed to optimize water recovery and reuse of available water at Khumani Mine. Due to the high clay content, wet processing of ore through jigs, screens, and cyclones was suggested, requiring large amounts of water and dilute slurries. In order for the project to succeed, optimization of water recovery was important. Drivers were the scarcity of water, erratic rainfall conditions, and need to prevent contamination of groundwater resources. The allocation of raw water meant that consumption of less than 0.09 m3/t was ideal.

Equipment Selection

Concerns with high evaporation rates and inconsistent underflow densities at Khumani meant that alternate thickening and disposal options needed to be found.

Testing was undertaken to determine if paste technology would work for iron ore processing. System considerations included upstream process requirements and thickening, pumping, and deposition limitations. Once bench-scale thickener tests concluded, a paste residue site was identified that had natural sloping contours to encourage runoff and adequate storage capacity for the life of the mine.

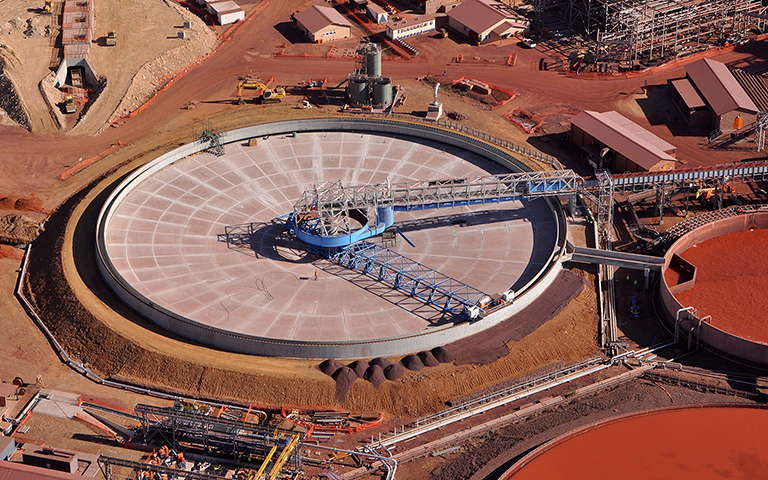

Final design incorporated large high-rate and secondary paste thickening technology. A 90 m-diameter primary Titan™ traction thickener is situated at the main plant and an 18 m-diameter Deep Bed™ paste thickener at the paste disposal facility. Later, an additional primary thickener and paste thickener were installed in the same configuration to increase production. The primary thickeners recover the majority of the water. Underflow from the primary thickeners is pumped to the paste thickeners, recovering 70 percent by volume of the water in the underflow of the primary thickener, which is then pumped back to the main plant. Total water recovery is approximately 96 – 98 percent. In addition, due to paste deposition having >1 percent slope, tailings storage facility runoff can be collected and returned to the process.

| 90 m Traction Thickener | 18 m Paste Thickener | |

|---|---|---|

| Feed volume/rate | 18,000 m3/h | 288 t/h |

| Feed density | 1.03 t/m3 | 1.28 t/m3 |

| Underflow density | 29% solids by mass | 70% solids by mass |

| Varying feed size | <1 mm | <1 mm |

| Sheared yield stress | n/a | 20 Pa to 50 Pa |

Results

The traction and paste thickeners are operating very consistently. Successful implementation has clearly contributed to the overall water balances and successful operation of Khumani’s paste disposal facility.