Reduced Chemical Dose, Improved Water Quality

Solids CONTACT CLARIFIER™ With Tube Settlers

New Water Source Challenge

The Fort Payne Water District provides water for the City of Fort Payne and acts as a wholesaler to neighboring water districts. Treating 9 MGD, the trapezoidal concrete sedimentation basins built in 1968 were deteriorating, requiring an upgrade or replacement.

In addition to failing concrete, the basins experienced severe hydraulic short-circuiting and sludge removal issues. The traveling hydraulic vacuum sludge removal system would often get stuck in the sludge, requiring the basins to be drained and hosed out. At times, air pockets would develop in the vacuum hose, depriming the siphon and breaking the sludge vacuum.

In 2009, Fort Payne began working with Constantine Engineering to replace the sedimentation basins to improve filter run times and filtrate quality.

When selecting the equipment for the new system, the operators wanted to correct the issues associated with the old system. The previous system was mechanical with many moving parts, resulting in frequent maintenance.

Many flocculation and clarification technologies were considered, including solids contact clarifiers, because they have very few moving parts and are housed within a compact footprint.

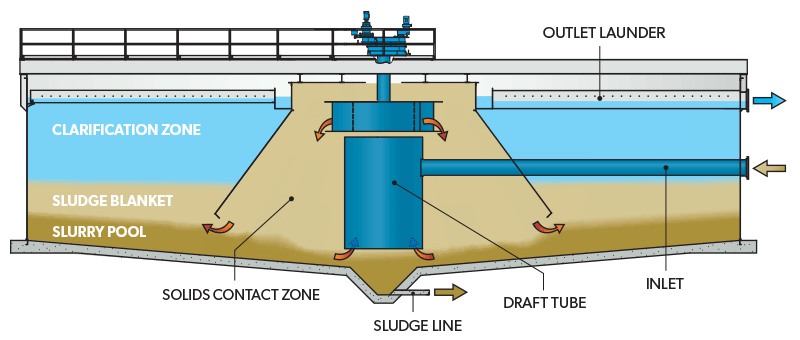

WesTech’s Solids CONTACT CLARIFIER™ provides flocculation and clarification within the same basin, eliminating the need for separate flocculation basins and also reducing clarification basin size. Operators were impressed with the compact nature of, and quality of water produced by, WesTech’s Solids CONTACT CLARIFIER.

The Fort Payne Water District decided to use solids contact clarifiers for sedimentation and, in 2011, installed two WesTech Solids CONTACT CLARIFIERs. As an enhanced flocculation device, the solids CONTACT CLARIFIER provides high-volume internal solids recirculation combined with gentle mixing. The internal solids recirculation results in enhanced flocculation and improved water quality.

| Quantity | 2 |

|---|---|

| Flow rate | 3,125 gpm per unit |

| Dimensions | 65 ft2 |

| Side water depth | 18 ft |

| Hydraulic loading rate | 0.9 gpm/ft2 |

| Internal recirculation rate | 18,750 gpm |

| Flocculation well detention time | 30 min |

| Total detention time | 180 min |

| Motor HP | Rake arm drive: 0.5 Impeller drive: 5 |

To further improve settling efficiency, tube settlers were installed. Tube settlers allow small floc particles to come in contact with each other, creating a faster-settling particle and better clarified water. Through the superior design of the solids CONTACT CLARIFIER and the use of tube settlers, Fort Payne reduced clarified effluent turbidity by 70 percent over its previous clarifiers.

| Material | PVC |

|---|---|

| Angle from horizontal | 60° |

| Vertical height | 36 in |

| Plan area | 3,500 ft2 |

Brandon Light, the Fort Payne treatment plant manager, said, “Turbidity has gone dramatically down and we were able to cut our coagulant dose in half.” Fort Payne plant operators believe this is the highest quality water they have seen in years from the clarification process, even with the reduced coagulant dose.

Before the solids CONTACT CLARIFIERs were installed, the water clarity onto the subsequent multimedia filters was so poor that the filter media could not be seen and backwash cycles were frequent. With the new clarifiers, filter media is clearly visible and filter run times have been doubled. These filters can now run more than 100 hours before needing to be backwashed.

| Raw Water | 1968 System | 2011 WesTech Upgrade | |

|---|---|---|---|

| Turbidity | 12.9 NTU | 1.25 NTU | 0.4 NTU |

| TOC | 3.61 mg/L | 2.38 mg/L | 1.82 mg/L |

| Color | 6.85 Pt-Co | 0.16 Pt-Co | 0.0 Pt-Co |

| Coagulant dose | n/a | 25-31 ppm | 13-15 ppm |

| Filter run time | n/a | 40-50 hrs | More than 100 hrs |

The solids CONTACT CLARIFIERs have increased water quality while decreasing costs through reduced coagulant dosage and longer filter run times. To eliminate recoating, stainless steel was installed at the air/water interface. Operation and maintenance have been simplified through WesTech’s robust, stationary equipment. The operators at Fort Payne are pleased with the small footprint and ease of operation.

“Turbidity has gone dramatically down and we were able to cut our coagulant dose in half.”