Mine’s Innovative Process Succeeds With WesTech’s Responsive, Customized Retrofit

Problem

A mine in the Western U.S. developed an innovative approach to removing gold from ore, one that promised to significantly increase its gold production. The traditional carbon-in-leach (CIL) approach wasn’t working well for the mine because the ore in its area contains carbon. Specifically, the cyanide-based chemistry formulated to leach gold from ore into solution and then deposit the dissolved gold onto carbon media failed to work efficiently because the carbon in the ore either retained or adsorbed too much of the gold.

To more efficiently recover gold from its carbon-containing ore supply, the mine developed a resin-in-pulp/resin-in-leach (RIP/RIL) solution that relies on thiosulphate leaching combined with resin media.

The new leaching process worked well when it came to extracting more gold from the ore, but not when it came to the company’s existing CIL equipment. The smaller, smoother resin media were prone to pinning, a condition in which flow pressure pins the resin to the interstage retention screen, and blinding, a condition in which resin gets stuck in the screen’s gaps. Both conditions impeded flow through the mine’s CIL circuit and therefore affected the mine’s ability to meet its gold-production target. (A circuit is composed of a series of tanks through which leachate flows. Each tank contains media to trap the gold that remains in solution through the extraction process in the previous tank.)

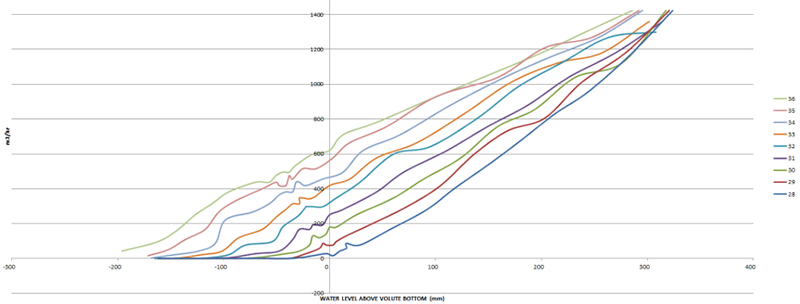

The mine initially thought that if it increased pressure, it could achieve greater throughput. But the increased pressure merely pushed the resin media against the interstage screens in the circuit’s tanks. This not only reduced throughput but also elevated the slurry level in the tanks.

The mine thought it needed all-new equipment to solve its throughput problem.

Analysis of Alternatives

Because the mine was using traditional WesTech Interstage Screens in its new circuit, the area’s sales representative reached out to WesTech engineers for help. An engineer immediately responded to the call for assistance, visiting the site to see first-hand the conditions that were causing impeded throughput.

The engineer worked directly with the mine’s plant manager to learn not only where the company’s CIL equipment was failing to meet the mine’s needs, but also to discover what the mine hoped its new process would achieve. After assessing the cause of the problem, which was related to the mine’s new media, and keeping in mind the mine’s target for gold extraction, the engineer identified an alternative to replacing the mine’s existing equipment: The mine could modify the equipment it already had to work with resin media.

The mine’s initial solution, purchasing all new equipment from a competitor, would have incurred a substantial cost. This made it difficult for the mine to achieve management buy-in.

Recommended Solution

After developing a meticulous understanding of the company’s goals, the WesTech engineer proposed a retrofit solution that was based on research and development (R&D) that WesTech had previously done for a mine in Brazil.

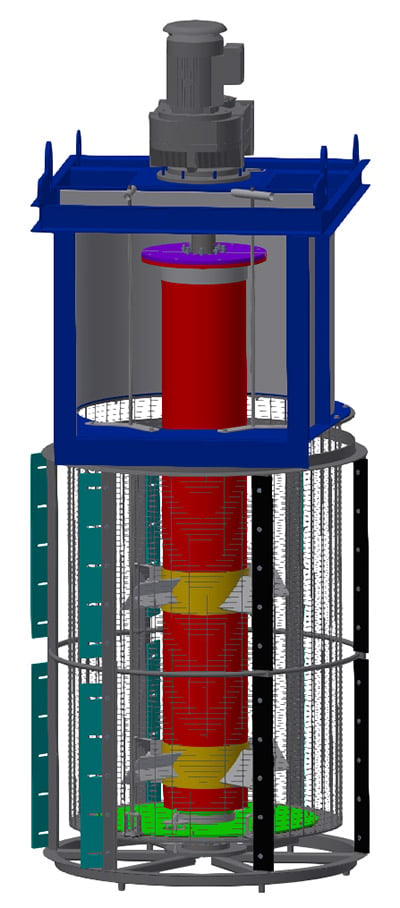

This R&D had yielded a new product innovation for WesTech, a lift-assist pumping screen that simultaneously screens and pumps. Although the mine in the Western U.S. was on a slope and was using gravity-fed (as opposed to pumping) equipment, the engineer determined that with the new media, the mine’s process would benefit from a modified version of WesTech lift-assist pumping screen technology.

The mine accepted this proposal, initially considering it an interim solution that it would replace when it gained management buy-in for all-new equipment.

Implementation

To demonstrate WesTech’s commitment to the mine’s success, the engineer proposed a three-step pilot study to determine the least costly solution that would help the mine meet its production goals.

The first step was to replace the pulse blades on two existing interstage screens with wider blades that the engineer could adjust to reduce the space between the blades and the screen. The purpose of this step was to determine if the new blades alone could create enough force to reduce pegging in the interstage screens.

The second step was to increase the rotations per minute (RPM) of the pulse blade to determine if increased force, in conjunction with the new pulse blades, could sufficiently reduce pinning.

The final step was to retrofit the two MRSs with modified lift-assist pumping technology.

“We took some of that R&D information, and without having to replace all of their equipment, we retrofitted some of their equipment with lift-assist pumping,” explains Paul Peterson, the WesTech Special Projects Engineer who worked on-site with the mine manager.

While the pumping screen WesTech designed through its initial R&D included a large conical pump, the engineer saw that for the U.S. mine, simply changing the shape of the impeller and increasing the rotational speed could provide the balance of agitation and pressure that the mine needed to improve throughput.

The modified impeller causes an agitation that makes the fluid flow upward without pumping it. Increasing the speed with this impeller-blade design allows more backwashing, automatically clearing the screen baskets that were prone to pinning. The modified impeller also added a slight vector of flow.

The retrofit design included a cage that rotates at the same speed as the impeller. The cage has blades that, with the correct placement, create a pressure pulse on the basket screens that helps pull away pinned media so that fluid can flow through.

In addition to the lift-assist pumping mechanism, the engineer replaced the company’s existing basket screens. The replacement screens featured gaps that were optimized to work with the mine’s specific RIL/RIP process. The basket-screen redesign also included reinforced backer rods to mitigate wear caused by increased loads.

After seeing substantial improvement with the pilot-study retrofit, the mine replaced all 44 of its interstage screen internals with the new lift-assist equipment.

Results

Once considered an interim solution that would do until it could persuade management to purchase a much costlier “Cadillac” solution, the mine now calls its WesTech retrofit solution “The Cadillac.” The mine’s system throughput and gold capture increased significantly, resulting in a substantial economic return. Owing to WesTech’s investment in the mine’s success, the mine has more than achieved its target gold-production goals while enjoying reduced operator efforts, all at a fraction of the cost of all-new equipment.