City of Lebanon Updates Aging Equipment

CONTRAFLO® Solids Contact Clarifier

Problem

In early 2004, the City of Lebanon Authority wanted to expand its water treatment plant (WTP) capacity from 10 million gallons per day (MGD) to 20 MGD (37,854 m3/d to 75,708 m3/d). The plant, which was updated in 1972, treated surface water from two different sources. The first source was Siegrist Dam, an impound reservoir approximately 14 miles away in Schuylkill County. The second source was Swatara Creek 3 miles away. The plant had the capability to use each source independently or combine them.

The 10-MGD (37,854 m3/d) plant treated the source water with coagulation chemicals and then sent the water through clarification and filtration processes before storage and disinfection. Finally, the plant used the treated water to feed three separate other water systems.

Because surface-water chemistry fluctuates with inclement weather swings and seasonal temperature changes, the water can become difficult to treat, posing a real challenge to WTP operators.

Analysis of Alternatives

Good pretreatment is the key to achieving efficient filter performance and economical operation. For example, pretreatment with a solids contact clarifier can result in lower solids loading on the filter and longer run times before backwashing is required. This is important because less frequent backwashing extends filter media life and produces less waste. In addition, since the backwash process is supplied with the filter permeate, less frequent backwashing translates into higher plant productivity.

Proper pretreatment also significantly reduces organics, which helps plants to comply with disinfection byproduct (DBP) regulations.

Recommended Solutions

With a need to expand the plant and upgrade some of its existing equipment, the city’s engineer, Gannet Fleming, Inc. of Camp Hill, Pennsylvania, requested that the city consider the CONTRAFLO® Solids Contact Clarifier for the upgrade. Gannet favored the CONTRAFLO system for its improved (and ease of) operation.

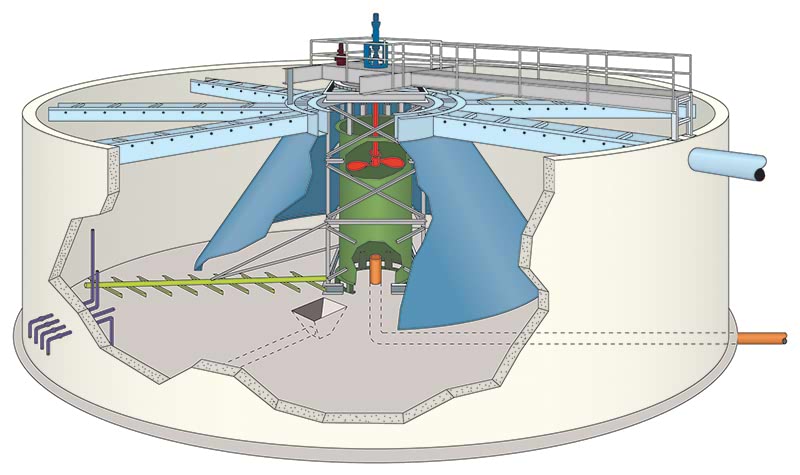

The CONTRAFLO is a true solids-contact clarifier that combines flocculation and sedimentation in a single basin. Plants can use it for pretreatment to clarify, remove iron, soften (via lime or caustic softening), neutralize waste, or to reduce organics.

The CONTRAFLO has several unique features when compared with other contact clarifiers, including a high-efficiency marine propeller, an extended draft tube, a roller-tooth scraper drive, and low-profile scraper arms. The marine-type propeller is located inside the draft tube, offering a ducted impeller configuration for internal recirculation. It operates with a smooth pumping action, recirculating six to 10 times the forward flow. The varying pitch along the entire radius of each blade produces a constant flow velocity across the entire propeller diameter. This results in enhanced particle collisions that quickly produce a larger floc while minimizing particle shear.

The draft tube that houses the marine propeller extends all the way to the basin floor, where settled sludge accumulates. The propeller generates an upflow inside the draft tube, which lifts previously settled sludge and mixes with influent flow to produce a higher solids concentration in the reaction zone, resulting in enhanced flocculation and a better solids contacting ratio. Operators have the ability to use sludge blanket operation, where a deeper sludge bed outside of the cone can act as a filter and catalyst, collecting small particles of sludge and forcing chemical reactions to completion. Operators can also adjust and fine-tune the mixer while the unit is operating. In addition, they can service the roller tooth gear and pinion scraper drive without removing the drive platform.

Unlike drives that can contain several gallons of oil (which operators must change regularly), the CONTRAFLO scraper drive requires only grease for lubrication. The low-profile scraper arms have a high-strength, low-weight tubular design with replaceable plows. In contrast to box-truss designs, they can be easily repaired and repainted.

Implementation

Phase 1 of the project was bid in 2005. The city began construction the following year. The design-build operation was for two CONTRAFLO Solids Contact Clarifiers in new concrete basins that were 90 feet (27 meters) in diameter. Each of these upflow clarifiers had a design capacity of 7.49 MGD (28,800 m3/d).

Upon seeing CONTRAFLO’s performance after the first phase of its expansion was completed, the City of Lebanon Authority selected CONTRAFLO for the second phase, which entailed retrofitting the plant’s existing clarifiers. Because these clarifiers had flat bottoms, the CONTRAFLO system for Phase 2 required a slightly different design.

Phase 2 was started in 2010 and consisted of retrofitting the two units that were part of the original (1972) plant with new internals, each designed for 7.49 MGD (28,800 m3/d).

Results

Although the plant’s capacity has increased to 20 MGD (75,708 m3/d), its current design flow is for 11 MGD (41,640 m3/d) per its Pennsylvania Department of Environmental Protection (DEP) permit. Its current operating flow averages 8.0-8.5 MGD (30,283-32,176 m3/d).

Today, even after 15 years of operation, Plant Manager Barry Brandt still expresses his appreciation for the CONTRAFLO units. Calling out the equipment’s operation and design, he reports that the plant has never had to replace a drive or motor on the units. Brandt also praises the CONTRAFLO’s sloped floors, which save the plant three to four hours during yearly cleaning.

“The flat floor configuration requires more time to squeegee the sludge to the center drain,” says Brandt.

After cleaning the CONTRAFLO units, it takes only two to three days to return them to optimal performance. In contrast, it takes about two weeks to bring the flat-bottom units back to optimal performance.

Through use of proper chemical addition, the plant is able to minimize solids loading on the filter. Furthermore, CONTRAFLO efficiencies have enabled the plant to cut back on its chemical consumption, resulting in an overall improved operation. The plant’s filter backwash frequency is 72 hours, as regulated by the Pennsylvania DEP.

When environmental conditions affect the normally low turbidity of the plant’s source waters, the CONTRAFLO system effectively treats the poorer-quality waters, producing water quality with an average of less than 5 NTU. Regardless of its current water quality, the system is able to provide the City of Lebanon Authority’s dual media filters with a low turbidity loading for good performance and longevity.