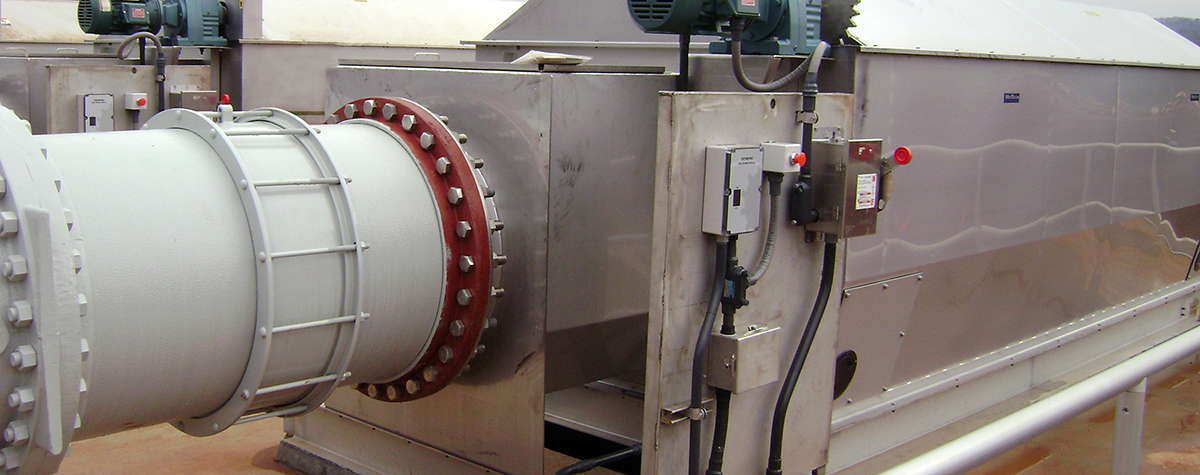

CleanFlo™ SHEAR™ Rotary Drum Screen

CleanFlo™ SHEAR™ Rotary Drum Screen Overview

For years, rotary drum screens have been the industry’s choice for applications requiring high solids removal efficiency at an economical cost. Our innovation offers direct-drive propulsion for drum rotation, eliminating the messy and maintenance-prone chains and sprockets.

The primary advantage of drum screens is eliminating debris carryover. Debris remains inside the screen until discharge. Unlike conventional moving media screens, there are no seals with a drum screen. In addition, there is no chance for debris to bypass the screen medium.

The CleanFlo™ SHEAR™ rotary drum screen can be manufactured to suit virtually any screening application. Screen mediums are available in stainless steel wedge wire, woven mesh, or perforated plate. Selection is based on many factors, including application, type of solid, screening efficiency, flow capacity, and owner preference.

Screen openings can range from 0.010 to 1/8 inch (0.254 to 3.175 millimeters) with clean water flow capacities up to 20 MGD (75,708 m3/d).

Benefits and Features

Applications

- Solids removal to protect downstream process and equipment

- Primary treatment in lieu of clarifiers

- Solids recovery in industrial process streams

- Total effluent treatment for industry prior to discharge to a municipal system

- Fine screening prior to membrane treatment

- Applications containing stringy or fibrous debris

- Sludge screening

- Sludge thickening

Features

- Chain drive eliminated

- Heavy duty direct drive unit mounted above the cylinder

- Drum tracking that is smooth and consistent

- Main framework is constructed of ¼" stainless steel to provide freestanding support for the screen

- The screen is supported by oversized trunnions at each end of the drum

- Seal precision ball bearings are lubricated from the inside out through a center shaft lubrication port

- Screening surface of the drum screen is perpendicular to the flow of the incoming stream

Benefits

- No problems associated with chain drives such as chain stretch, chain corrosion, lubrication, and tracking problems

- Improved accessibility to the direct drive unit

- Shock loads to trunnions are reduced, maximizing trunnion wheel life

- Grease can be applied at an external manifold without the removal of covers

- Minimizes solids from binding and adhering to the drum screen