South Valley Clarifier Upgrade Improves Efficiency

COP™ Clarifier

Always Upgrading

The South Valley Water Reclamation Facility (WRF) came into operation in 1985. The facility started with two clarifiers and accepted 18 million gallons per day (MGD) of influent wastewater. In 1992, WesTech installed two segmented blade clarifiers. South Valley’s influent subsequently increased to 35 MGD and the facility soon upgraded to six functioning clarifiers. In 2003, South Valley retrofitted its existing clarifiers to COP™ (Clarifier Optimization Package) clarifiers from WesTech.

A new plant was built near South Valley WRF and some of the older plant’s flow was diverted to the new facility.

South Valley WRF now takes on 20 MGD, serves nearly 350,000 connections, and serves as an overflow for the new plant.

| Quantity | 6 |

|---|---|

| Dimensions | 150 ft. diameter |

| Sludge collection | Spiral blades |

| EDI configuration | Dual gate |

COP Clarifier

WesTech was selected to retrofit the six clarifiers to make them more efficient. The COP design reaches a higher efficiency with the combination of the dual gate energy dissipating inlet (EDI), flocculating feedwell, and spiral rake blades.

South Valley uniquely uses both dual gate EDIs and LA-EDIs. Each of these EDIs uses impinged flow, which is achieved by redirecting the flow against itself. This decreases the kinetic energy of the mixed liquor as it enters the feedwell. The disadvantage of the LA-EDI is that it is depth dependent, needing a deeper basin to perform properly and not disturb the sludge blanket.

The flocculating feedwell further decreases the flow energy and allows a uniform radial and quiescent settling. South Valley’s feedwell is submerged, which allows for the skimmer arm to remove scum from the entire radius. The mixed liquor remains within the feedwell and does not exit over the top due to the flow and density of the mixed liquor.

WesTech spiral blades move settled solids to the center of the tank more than four times faster than the segmented rake blades the facility previously used. The blades do this by remaining in constant contact with the solids throughout the revolution, quickly guiding them to the slanted hopper at the center of the tank to be removed or recirculated back into the biological process. In contrast, the segmented blade moves the solids a little each revolution, each blade slowly pushing it closer and closer to the center of the tank.

Moving the solids quickly is vital in a secondary clarifier. Failing to do so can lead to secondary phosphorus release or denitrification caused by anaerobic conditions in the sludge blanket, especially in warmer-temperature water.

Successful Results

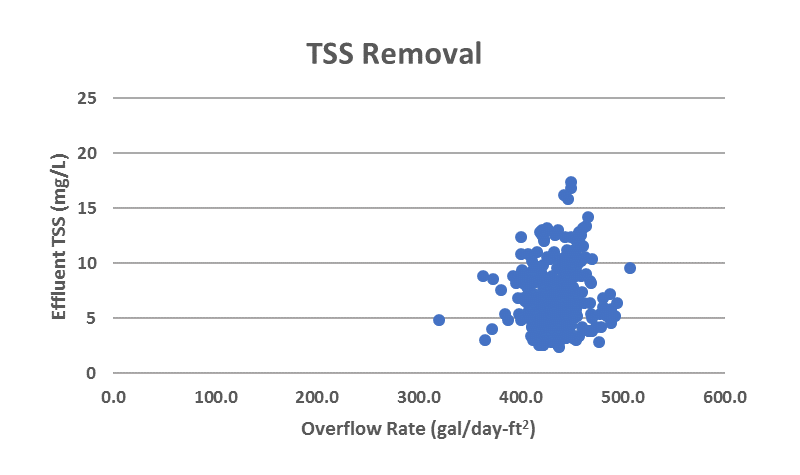

South Valley WRF must maintain certain effluent standards to comply with its permit for pollutant discharge. One of the limits it must meet is for total suspended solids (TSS). South Valley has a weekly discharge limit for TSS of 35 mg/L as well as a monthly limit of 25 mg/L.

On average, South Valley runs its clarifiers at an overflow rate of 430 gallons per day per square foot. It also has a very low average sludge volume index (SVI) of 80 mL/g. The low SVI results from reduced waste rates into the mixed liquor suspended solids (MLSS) or from having a higher ratio of MLSS compared with the waste. This allows heavier and more dense solids particles to form, but the heavy particles descend quickly, not trapping the fine suspended solids that leave the clarifier and create effluent TSS.

The TSS removal graph shows a relationship between the effluent TSS and the clarifier overflow rate throughout a year. WesTech’s spiral blade clarifiers are easily able to settle the solids, keeping the TSS below 20 mg/L, and far below South Valley’s permit, every day of the year. These numbers are impressive considering the facility’s higher overflow rate and low SVI.

The facility is very pleased with its COP spiral blade clarifiers and their functionality. The low TSS values the clarifiers produce prove their success. They live up to their name, optimizing each component of the clarifier from influent to effluent. The clarifier produces concentrated sludge at one end and clarified water at the other. Each component that makes up the COP clarifier requires very little maintenance but continues to do the job required.

Randy Wyness, South Valley’s facility operations director, was asked to comment on what the facility likes about its clarifiers. He responded: “Reliability. It’s nice to have that kind of reliability.” Wyness appreciates the longevity of the clarifiers, particularly their drives, which South Valley has had from the beginning. The facility is pleased that the clarifiers continue to perform the service it needs while efficiently keeping TSS far below its permit level.