EvenFlo® Retrofit Improves Thickener Performance

Patented Design Reduces Dosage, Improves Clarity

Problem

A Wyoming facility mines trona and produces soda ash. The soda ash is used in many products, including baking soda and soap. It is also used in processes such as glass making, chemical processing, paper manufacturing, and water treatment. More than 90 percent of the nation’s soda ash comes from Wyoming deposits.

Soda ash production requires a hot dissolution process in which recovery of the hot pregnant liquor is paramount. The liquor is recovered in a primary clarifier where overflow clarity is important. Any residual suspended insoluble solids in the overflow lowers the grade of the final product, so as a last step, polishing filters are used to remove them. Insoluble solids in tailings from soda ash processing include solids such as fine clays and silts.

The soda ash facility is constantly seeking to improve the recovery and purity of its final product.

Analysis of Alternatives

Improving the operation of the primary clarifier reduces the load on the polishing filters. The primary clarifier, installed over 35 years ago, was equipped with a conventional shelfed feedwell. The pregnant slurry is fed through down pipes that are elbowed at 90 degrees at the discharge end.

The facility invited WesTech process engineers to conduct an audit of the clarifier. The results showed that the mine was experiencing traditional problems with this type of feedwell, such as:

- Poor flocculation: Only a small area around the inlet of the feed provided good mixing.

- Short circuiting: The feed stream momentum carried the flow prematurely down and around the wall, past the shelf, and out of the feedwell.

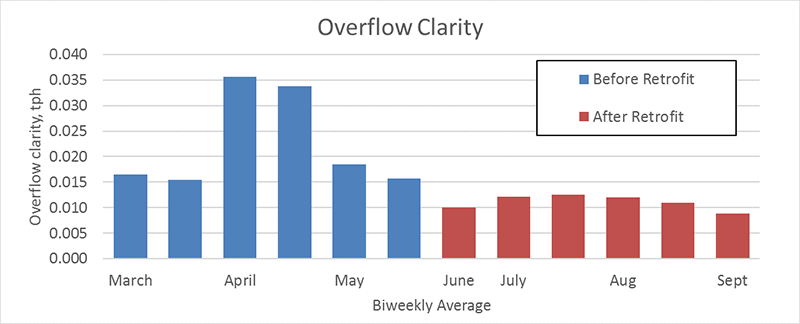

- Poor overflow clarity: The overflow included insoluble solids.

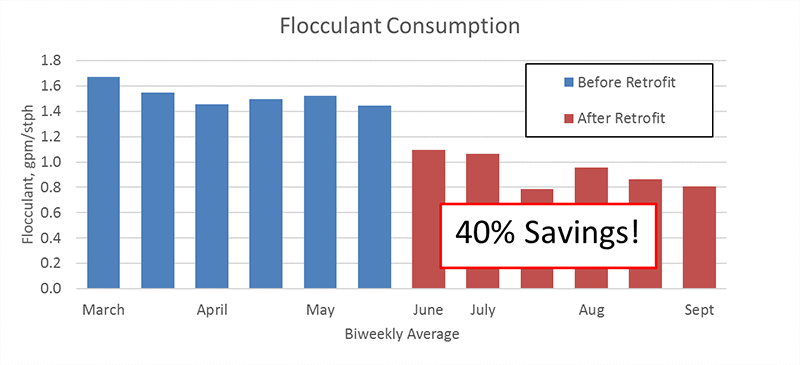

- High flocculant cost: High flocculant dosages attempted to compensate for poor feedwell performance.

The mine had previously conducted optimization studies, investigating feed pipe arrangement and flocculant dosages. WesTech presented the EvenFlo® feedwell as an option to minimize the overflow of suspended solids and reduce flocculant use. The simple two-stage design of the EvenFlo feedwell – which requires no vanes, baffles, or deflectors – was of particular interest.

Chosen Solution

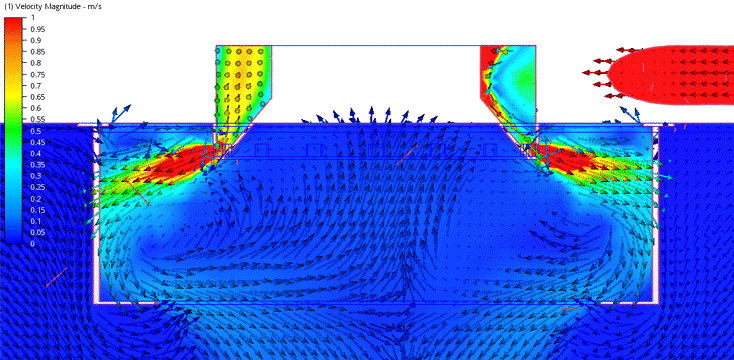

The EvenFlo feedwell has a patented design that addresses the shortcomings of conventional feedwells. With the WesTech EvenFlo design, the feed stream enters tangentially into an inner raceway (first stage) and is then directed radially into the outer feedwell (second stage). The simple design provides optimum flocculation conditions between the inner raceway and the outer feedwell, creating consistent mixing and recirculation flow in the full feedwell.

Implementation

Retrofitting the facility’s existing clarifier required an audit and analysis of the bridge to ensure that it would support the retrofit. The inner raceway is partly above water and is normally supported by the bridge.

The EvenFlo design was customized to receive the facility’s existing feed pipe arrangement. At this site, the down pipe feedline was fitted inside the inner raceway channel. The site provides multiple feed pipes to ensure continued operation while the previous pipe is cleaned. There are four feed pipes, but only one is active at a time. Because it is a hot dissolution process, the clarifier is insulated and under a roof. The EvenFlo was designed to fit within the roof support.

The primary clarifier tank had settled, and it was sloping to one side. The plant had earlier provided new footings to prevent any further settling, but the overflow exiting the clarifier flowed heavy to the downhill side. WesTech supplied modified overflow weirs to level the overflow launder, so there is now no preferential flow pattern.

Following the retrofit installation, the feedwell performance was limited by the multiple feed pipes. Computational fluid dynamics (CFD) studies showed that the inner raceway flow was baffled by the off-line feed pipes. The length of the feed pipes was shortened to rectify the problem.

Results

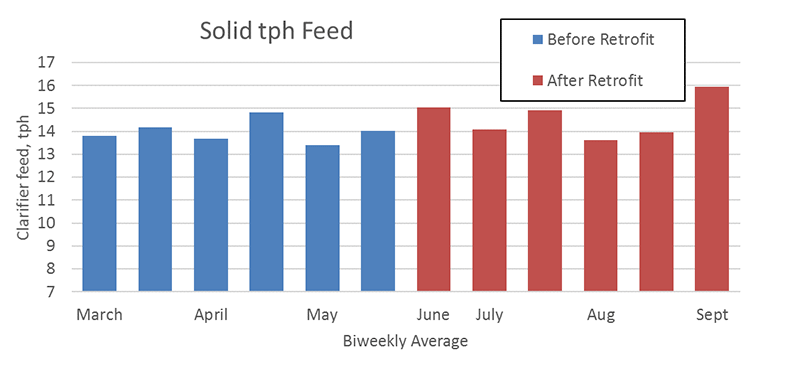

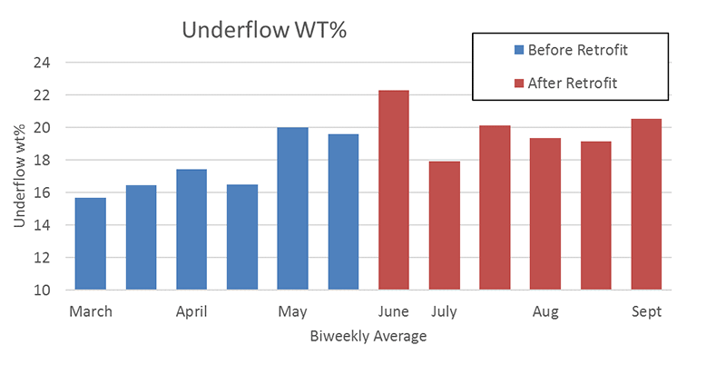

The primary clarifier performance at the trona mine and processing facility showed significant improvement in overflow clarity, reduction of flocculant dosage, and increase in underflow density when comparing the thickener performance 11 weeks before the EvenFlo retrofit with the performance 11 weeks after the retrofit.